Hammer Disc Introduction

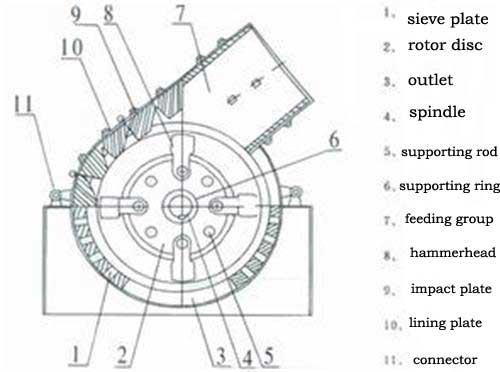

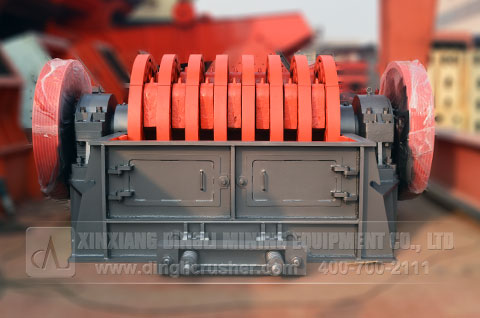

Hammer crusher is special for crushing medium hardness materials of limestone. The working principle is crushed and impacted by impact plate. Hammer crusher mainly consists of shell, rotor, liner, and outlet. Hammer disc plays a major role in the whole equipment. Now we will detail them.

Structure & Function

Also called rotor plate, hammer disc is mainly used as hanging hammerhead that is the main parts of hammer crusher. Hammerheads are averagely hanged in the disc and disc is equipped in the spindle that avoids directly impact of loose and broken conditions.

Hammer Disc Texture and Processing

In the operating, there is inevitable impacting, so we should use high wear resistant materials. In operating we should deal them with high manganese steel carburizing heat treatment to improve its wear resistance condition. Also we can improve lining speed and service life with enlarging hammer disc diameter.

Hammer Disc Maintenance and Upgrading

After long term operation, hammer disc will have wear and deformation condition that will influence hammer crusher capacity and even have to change a new rotor. If there are abnormal conditions in hammer disc, we should handle them. Such as, we can use surfacing electrode method in the outer of hammer disc. Also by using of wear ring, we hugely improved rotor service life.

Attention in Changing Hammer Disc

We should check the matching condition between keys and keyways ensuring it with no gap, check the controlling condition of locking parts or changing them if necessary in case of moving or dropping. Before using hammer crusher, please checking the loading and beneficiation technology in case of hammer disc and rotor broken.

NextContent:none