Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

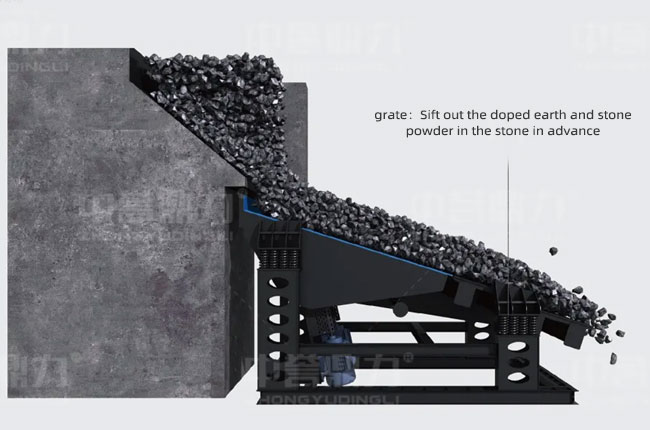

Sand Aggregate IndustryComprehensive Service ProviderZG series vibrating feeder adopts linear vibrating feeding, integral base structure. In the sand and stone production line, the large stones are uniformly and continuously sent from the silo to the crusher, and can play the role of coarse screening.

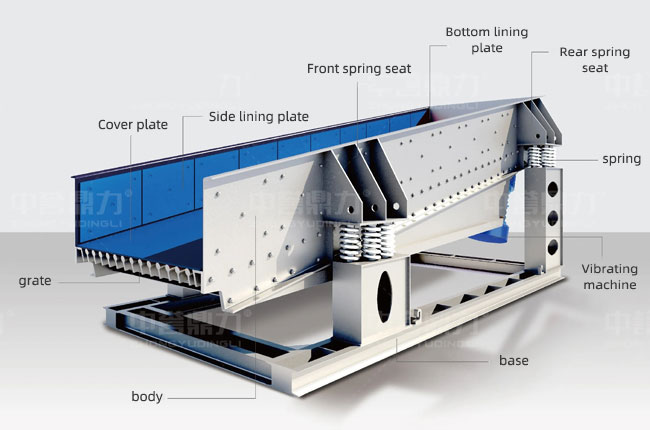

Vibrating feeder is composed of feeding tank body, vibrator, spring support, transmission device and so on. The vibration source of the tank body vibration feeding is the vibrator, the vibrator is composed of two eccentric shaft (main and passive) and gear pair, driven by the motor through the triangle belt drive shaft, and then by the drive shaft gear meshing passive shaft rotation, the main and passive shaft rotation at the same time, so that the vibration of the tank body, so that the material continuous flow, to achieve the purpose of conveying materials.

It is composed of a frame, a box, a base and a vibrator, among which the vibrator is a part of the whole equipment

By adjusting the relative Angle of the eccentric block can change the size of the excitation force, so as to control the amount of equipment feeding

Vibration source has two types of vibration motor and common motor with two shaft vibrator to choose from

At the same time of feeding, the material is coarse screened to improve the quality of finished material

Vibrator is the vibration source of the vibration feeder, eccentric block rotation produces centrifugal force to make the vibrator work, the feeding capacity is mainly determined by the vibration frequency of the vibrator, through no adjustment of the relative Angle of the eccentric block, so that the Angle formed in the inner eccentric block, can be stepless adjustment of the vibration force, change and control the flow of the feeder. Note: During adjustment, the positions of the eccentric blocks of the two vibration motors and the positions of the two groups of eccentric blocks of each motor should be consistent. Otherwise, due to the asymmetry of the exciting force, which leads to the imbalance of the vibration of the feeder, resulting in the damage of the vibration motor or the feeding body.

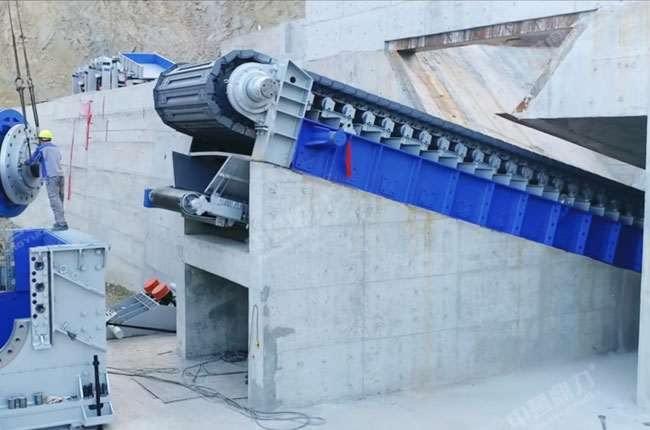

According to the actual application scenario, it can be divided into under the warehouse feeder and outside the warehouse feeder. The feeder under the warehouse is installed directly under the silo, saving the feeding height; The feeder outside the silo is installed in front of the silo, located under the silo.

Small investment

Small investment Not easy to plug

Not easy to plug Rich in types

Rich in types Easy maintenance

Easy maintenance

Technical Parameters of ZG Vibrating Feeder

| Model | Feed chute size (mm) | Max. feed size (mm) | Motor(model & exciting force)KN | Power (kw-6) | Capacity (t/h) |

|---|---|---|---|---|---|

| DLZGC0938 | 900*3800 | ≤500 | YU-50-6 | 3.7*2 | 150-200 |

| DLZGC1238 | 1200*3800 | ≤750 | YZU-65-6 | 4.2*2 | 250-400 |

| DLZGC1250Z | 1200*5000 | ≤750 | YZU-100-6 | 7.5*2 | 250-450 |

| DLZGC1250P | 1200*5000 | ≤750 | YE2-180M-6 | 15*2 | 250-500 |

| DLZGC1538 | 1500*3800 | ≤1000 | YZU-85-6 | 6.3*2 | 400-700 |

| DLZGC1550Z | 1500*5000 | ≤1000 | YZU-120-6 | 10*2 | 400-900 |

| DLZGC1550P | 1500*5000 | ≤1000 | YE2-180M-6 | 15*2 | 400-1000 |

| DLZGC2050 | 2000*5000 | ≤1200 | YE2-200L2-6 | 22*2 | 800-1500 |

| DLZGC2560 | 2500*6000 | ≤1600 | YE2-250M-6 | 37*2 | 2000-3000 |

Note: specifications are subject to change without notice. Please refer to the actual data of machine.

Free consultation on related issues.