Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderThe general configuration of gravel production line includes vibrating feeder, crusher and vibrating screen.

Capacity: 50 t/h-1000 t/h

Feed size is flexible

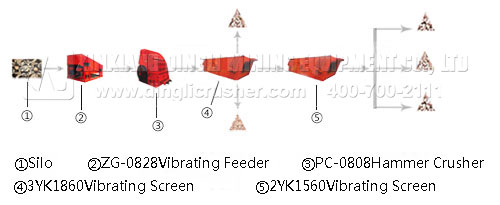

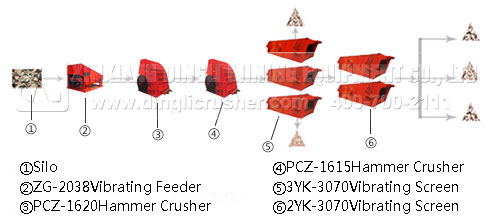

The general configuration of gravel production line includes vibrating feeder, crusher and vibrating screen. Besides, the large production lines also require dedusting and noise reducing equipment. Our hammer crusher can crush the material into required size for only once, so no secondary crusher is needed for small-scale production line.

The materials are firstly fed into PC0808 crusher by ZG0828 feeder. Then the crushed material is screened twice by vibrating screen for different grain sizes. The 100t/h small production line is widely used in current market.

The bulk material in the silo is successively conveyed from ZG 2038 into PCZ1620 and PCZ1615 for primary and secondary crushing. Then after being screened by 3YK3070 and 2YK3070, various types of finished material are discharged. With large capacity and high efficiency, such production line is generally applied in large production project.

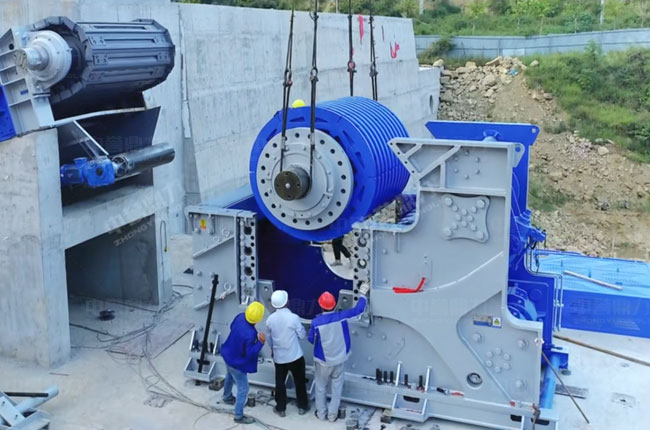

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.