Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderSand washing machine is a device for cleaning the impurities and other mixture of the sand.

Capacity: 30-600t/h

Feed size: ≤10mm

XS sand washing machine, also known as stone washing machine, is a bucket wheel washing equipment, mainly used for washing and dewatering of building sand materials. The series of sand washing machine is mainly used for cleaning sand and gravel material (such as removal of powder, impurities, etc.). Since a large number of washing methods are adopted during the operation, it is also called stone washing machine. The machine is generally used in the sand production line to improve the sand content and particle size, better meeting the national standards of gravel material. It can remove the impurities covering the surface of sand and gravel and damage the water vapor layer for coating sand, in order to facilitate dehydration, therefore, the machine functions well in efficient sand washing.

XS sand washing machine is featured with high cleanness, low power consumption, reasonable structure and less sand drain. In particular, the running parts separate the sand and water with high precision. Compared to traditional machinery, it has much less failure rate, becoming the first choice for sand washing.

When the sand washing machine starts to work, the motor drives the impeller to rotate slowly with the speed being reduced by the V-belt, reducer and gear. After entering the washing tank from the feed trough, the sand and gravel begin to roll under the driving of impeller and carry out mutually grinding. The impurities covering sand surface are removed and the water vapor layer coating sand is damaged so as to facilitate dehydration; at the same time, the water is added to form a strong flow for timely carrying off the impurities and small-proportioned foreign substances. With the sand being discharged through the washing trough of overfell, it indicates the sand washing have been completed. After the clean sand is carried off by the blade and poured into output tank through the rotating impellor, it completes the final process of sand washing.

Check whether the impeller and the motor are tightened before installation;

Water supply facilities should be made in advance;

Place and fix the sand washing machine in the cement base to avoid the burning of motor due to its shaking.

Simple structure, stable operation.

Applicable to all kinds of work environment.

Long service life, almost no wearing parts.

With little need for maintenance, it can greatly reduce costs.

With the bearings separating from water and aggregates, it can avoid the damage caused by the rust due to pollution of the machine.

With less loss of the washed aggregates and high cleaning efficiency, it can fully meet the requirements of high grade materials.

Regularly check the bolts and electrical components to avoid damage of the equipment;

Since the screen on the impeller is often soaked in water, please regularly check it to avoid rust fracture;

Regularly clean the impurities on the impeller to avoid reducing the amount of sand washing;

In case the bearing temperature is too high during the normal operation, immediately stop the running of machine to inspect and maintain the equipment;

Once there is noise generated by the roller during operation, stop to see if the lubrication is needed before boot.

With the new era rapidly leaping forward, more amount of sand and gravel material are required, but the output of fine gravel aggregate becomes scarcer. Then how should we meet people’s daily needs of gravel? This requires the investment in sand washing equipment. The birth of sand washing machine equipment is in line with the national trend of development, accelerating the construction of China's infrastructure.

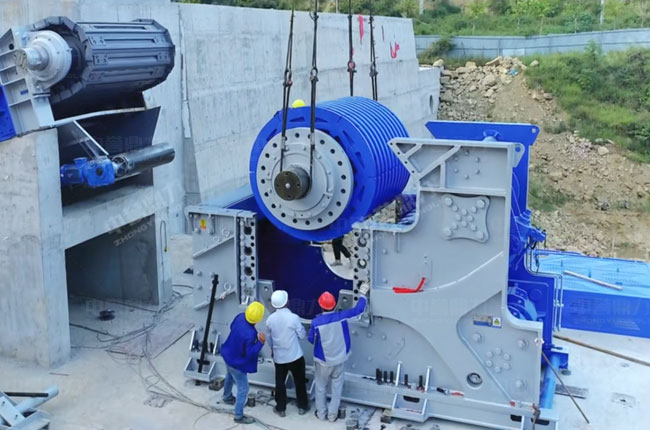

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.