Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderCrusher, also called stone crusher, can be divided into primary, secondary, and fine crusher by the size of feeding and discharging.

Capacity: 50-3000t/h

Feed Size: ≤2000mm

Crusher also called stone crusher is an indispensable mining machine for producing artificial sand and is an efficient method in solving the issue of lacking natural sand.

It is divided into primary, secondary, and fine crusher by the size of feeding and discharging. Coarse crusher is applied to crush the aggregates of over 350Mpa compressive strength, secondary crusher is used for the material with less than 200Mpa compressive strength and over 40% calcium content, and fine crusher is generally for powder grinding and sand making.

As the main crushing product of mining equipment, it plays an important role in selecting ore. From the literal meaning, we get to know its working principle as follows: the large blocks of ore or the pending ore are crushed into small size with their inner force and overcame by the outer force. The process of beneficiation often consists of two stages with primary crushing and grinding. As the indispensable mining machine, the crushing equipment provides a sound approach to solve the issue of exhaustion of natural sand.

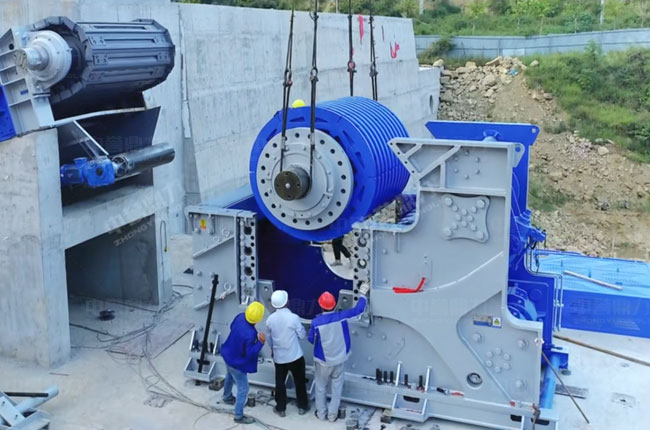

As a new type of mining crushing equipment, heavy hammer crusher is researched, developed, and advanced crushing technology by the state of art ideal. With super huge inlet gate, it can crush huge aggregates into the materials by meeting the standard of national infrastructure. Also heavy hammer crushing equipment is popular in its sector for lower energy consumption and adjustable output size.

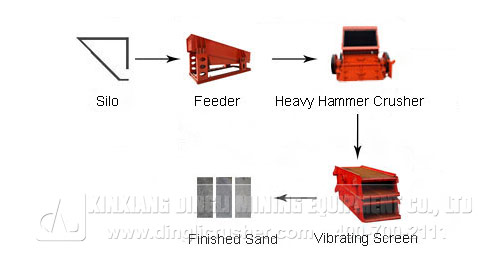

The heavy hammer crusher, produced by our company, is integrated crushing with shaping and with the name of two-in-one crusher, which is simplified production mode and gets the population of recommended brand of China. Advantage configuration is fed into feeding silo crushed by heavy hammer crusher (adjustable size), screened and graded by circular vibrating screen and last discharged finished material.

Similar to car, mining crushing equipment also needs maintenance. Crushing equipment maintenance is also a preparation of our later effective production.

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.