Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

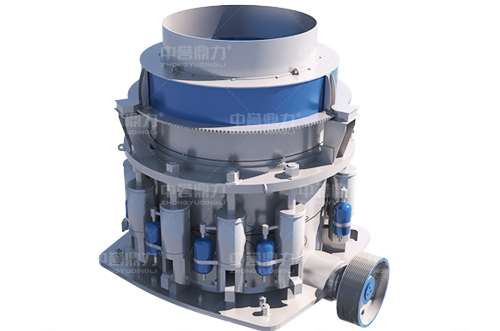

Sand Aggregate IndustryComprehensive Service ProviderDLHPT series multi-cylinder hydraulic cone crusher, developed and produced by Zhongyi, adopts the working principle of extrusion, which is commonly used in the medium and fine crushing link in the sand and stone production line.

1.The multi-cylinder hydraulic cone breaking structure with fixed spindle and eccentric sleeve rotating around the spindle is adopted.

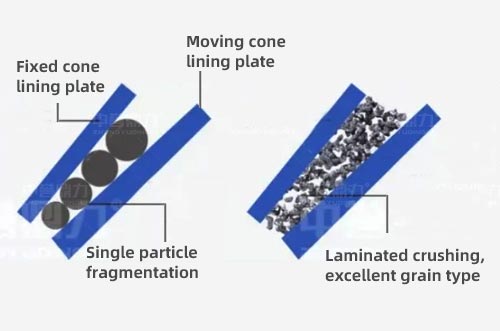

2.Layer compression crushing design, so that crushing between materials, high crushing efficiency.

3.And does not rely on the smaller discharge port to obtain smaller product granularity.

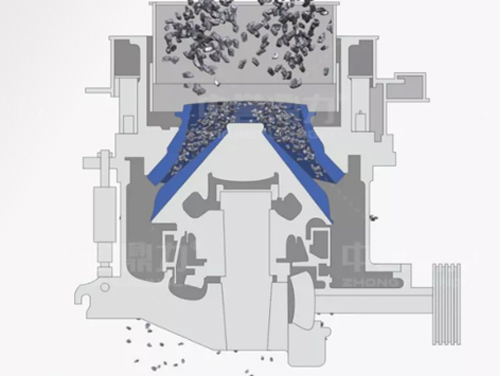

Multi-cylinder hydraulic cone crusher has simple structure, composed of motor, drive shaft, gear, eccentric sleeve, fixed cone, moving cone and other parts, using the extruding working principle, the motor through the triangle belt, drive shaft, bevel gear pair to drive eccentric sleeve rotation, moving cone in eccentric sleeve driven by the pendulum motion. The fixed cone and moving cone are sometimes close to and sometimes deviated from, and the materials in the crushing chamber are squeezed and crushed 360 degrees. The broken materials are discharged from the lower discharge port.

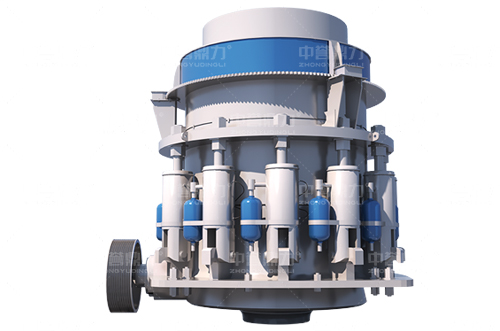

Bumper oil circuit adopts large diameter tubing, large capacity accumulator, better buffering performance, more rapid response, more stable operation of equipment.

Fixed spindle, strong bearing capacity, more compact equipment structure, small volume, high production efficiency.

Supporting floating installation base, installation is simpler, save time and effort, at the same time to the foundation requirements, low investment cost.

When the vertebral body wall is thickened, the original fixing mode of the lining plate is improved, without glue filling, which is more convenient and fast, and the maintenance cost is low.

Tin bronze bushing sliding bearing design, compared with traditional rolling bearings, equipment in high dust, high impact environment can still maintain relatively high load capacity, and low production costs.

Consultation Details

By using the principle of intergranular lamination design, the flat and long materials are crushed first by squeezing each other, which can improve the crushing efficiency and the proportion of fine materials, reduce the needle and sheet materials to a large extent, the product has good grain shape, and the steel consumption of vulnerable parts is small.

Integrated hydraulic lubrication system design, prolong the service life of equipment, non-contact labyrinth seals no wear, increase the spherical floating seal, keep the cleanliness of lubricating oil. The fan adopts the German AKG air cooler, which has good cooling effect and prevents the equipment damage caused by the mixing of water and oil brought by water cooling.

The horizontal shaft is equipped with a temperature sensor to monitor the oil temperature in real time, so that the equipment runs smoothly. The transmission system adopts spiral bevel gear, which makes the transmission more reliable and stable, low noise and long service life.

| Model | Cavity Type | Size of Open Side Feed Port (mm) | Tight edge feeding size (mm) | Size of Discharge Port (mm) | Power (kw) | Weight (t) | Capacity (t/h) |

|---|---|---|---|---|---|---|---|

| DLHPT300 | C1 | 265 | 230 | 25 | 220 | 20 | 220-440 |

| C2 | 240 | 210 | 20 | 190-380 | |||

| M | 190 | 150 | 16 | 175-320 | |||

| F1 | 145 | 105 | 13 | 110-260 | |||

| F2 | 120 | 80 | 10 | 100-240 | |||

| DLHP500 | C1 | 370 | 330 | 38 | 355 | 40 | 425-790 |

| C2 | 320 | 290 | 30 | 380-700 | |||

| M | 245 | 210 | 22 | 330-605 | |||

| F1 | 180 | 130 | 16 | 270-535 | |||

| F2 | 150 | 95 | 13 | 200-430 | |||

| DLHPT800 | C1 | 375 | 350 | 38 | 560 | 70 | 545-1200 |

| C2 | 340 | 300 | 32 | 495-1050 | |||

| M | 310 | 265 | 25 | 470-950 | |||

| F1 | 265 | 220 | 17 | 385-730 | |||

| F2 | 210 | 150 | 14 | 310-600 |

Free consultation on related issues.