Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderApplication: making crushed sand and fine aggregates for highway, railway, airport, water conservancy, construction and other industries.

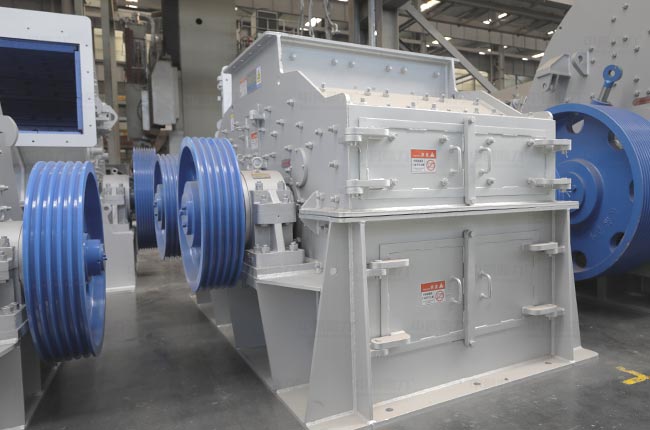

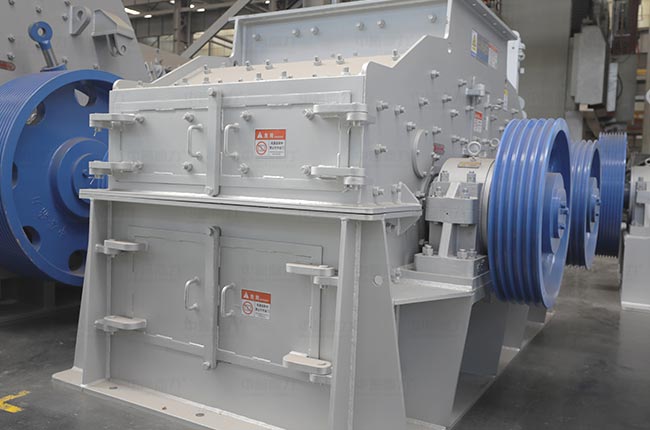

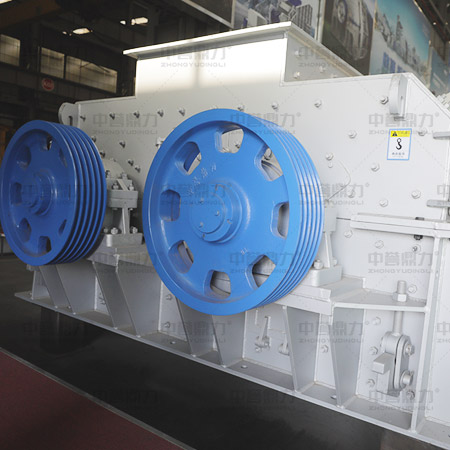

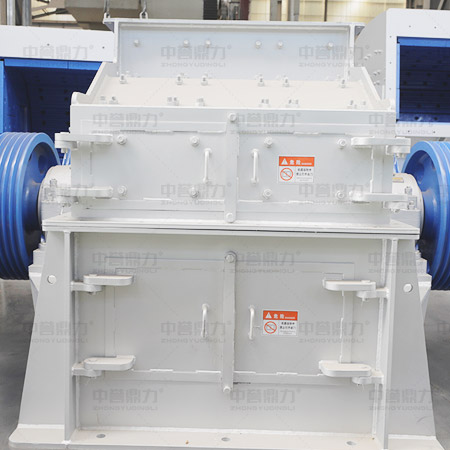

The ZSJ dual rotor sand making machine developed by Dingli integrates three advanced international technologies and adopts two outstanding achievements of domestic industry. It dramatically solves the drawbacks of single-rotor sand maker such as large energy consumption and poor shape of finished materials.

It is widely applied in stone, cement and various metallurgical slag industries for crushing and shaping soft and medium aggregates.

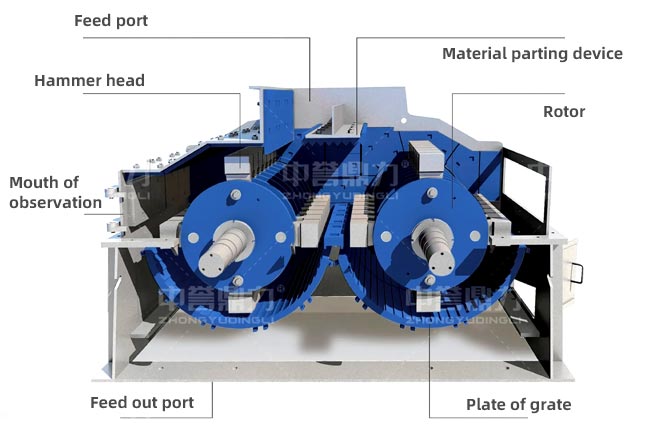

The structure includes a feeding port, a hammer, a rotor, a crushing chamber, a inspection and observation window, a grate plate with adjustable discharge size, and a material distribution device.

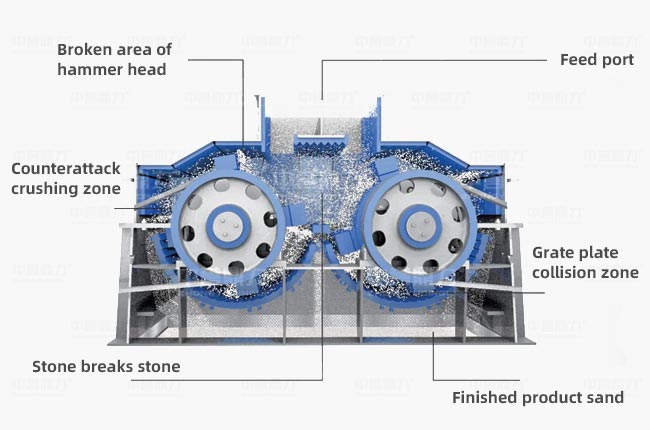

ZSJ sand maker is mainly composed of the body, crushing plate, upper and lower rotors, pendulum, rotary drive, sieve and other parts. During operation, with relative movement of the two rotors, the aggregates in the crushing cavity are firstly hit and crushed by the hammers of the first rotor, then rushed to the second rotor after obtaining a certain momentum. Since the second rotor moves in the opposite direction of flying materials, its speed of striking the aggregates is equal to superposition of two velocities. Through such cycles of repeated striking, the aggregates are discharged from the gap of grid.

Two feed openings ensure the raw materials are simultaneously distributed in the best crushing position of the two rotors.

The aggregate materials are thrown by the two rotors in a tangential direction, so the machine has large reduction ratio and high yield.

Repeated collisions facilitate self-shattering of the stone in the crushing cavity and reduce the abrasion of the hammers and the wear parts.

Adjustable grid gap design enables customers to obtain the finished materials with required particle size distribution and fineness modulus.

Improved Efficiency

Improved Efficiency Steady Operation

Steady Operation Hydraulic Device

Hydraulic Device Easy Maintenance

Easy Maintenance Multiple Functions

Multiple Functions Reasonable Gradation

Reasonable Gradation

Technical Parameters of ZSJ Dual Rotor Sand Maker

| Model | Rotor Diameter×Length(mm) | Power (kw-4) | Feed Size (mm) | Capacity (t/h) | Machine Size L×W×H(mm) |

|---|---|---|---|---|---|

| DLZSJ0808 | 754*218 | 2*(55-75) | <30 | 20-50 | 5500*1843*1600 |

| DLZSJ1213 | 1290*240 | 2*160 | <30 | 80-120 | 3400*2587*2050 |

| DLZSJ1238 | 1810*290 | 4*132 | <30 | 180-250 | 3600*3312*1900 |

| DLZSJ1416 | 1630*260 | 4*160 | <30 | 210-280 | 4712*3170*2300 |

Note: specifications are subject to change without notice. Please refer to the actual data of machine.

Free consultation on related issues.