Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderWith over 20-year history in mining industry, Dingli Mining Equipment Co., Ltd is expert in construction of limestone production lines.

Capacity: 50- 2000t/h

Main Equipment: hammer crusher

Based on decades of R & D in crushing equipment and self-owned stone plant, Xinxiang Dingli, through concentrated study, has manufactured the hammer crusher which crushes the aggregates to required size in one time with low investment, huge crushing ratio and high production efficiency. The production line is featured by high automation and super product quality. Equipped with new dedusting equipment, it can reduce the dust and meet the requirement of national environmental friendly equipment, that obtains recognition and support from the old and new customers in the market.

Limestone mainly includes CaCO3 that can directly be processed into stone material or burned into calcium lime.

Limestone can be calcium or slacked lime. With CaO as the main ingredient and lump as the common shape, the pure calcium lime is black while the impure is light gray or pale yellow. After absorbing moisture or water, the calcium lime will change into slacked lime with Ca(OH)2 as the main component. The slacked lime can be formulated into lime slurry, paste, motor and so on for being used as coating materials and tile adhesive.

In addition to be used as building material, the limestone is also the important raw material for numerous industries.

Limestone has a long histroy. It is the main ingredient for making cement, lime, and calcium carbide in modern industry. It is used as indispensable flux limestone in metallurgical industry. Through ultrafine grinding , the quality limestone is widely used for making paper, rubber, painting, coating, medical, cosmetic, feed, sealing, bonding and polishing products, etc.

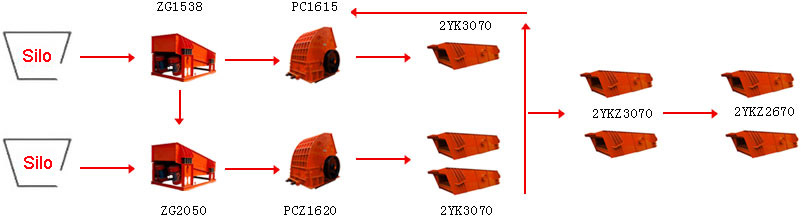

After being blasted from the mountain, the limestone less than 1200mm is sent into the vibrating feeder by dumper and then the crushed material is evenly fed into heavy hammer crusher for primary crushing. The large blocks coming out of the primary crusher will be transported to the next crusher for secondary crushing and shaping. After being screened by the circular vibrating screen, the block materials with unqualified size will be returned to the secondary crusher for re-crushing while the finished materials are conveyed to the stockpile. With the compressive strength of about 150Mpa, and soft rock of limestone, it is an economical and reasonable technique to adopt the two heavy hammer crushers to form a closed circuit for crushing twice in the limestone production line.

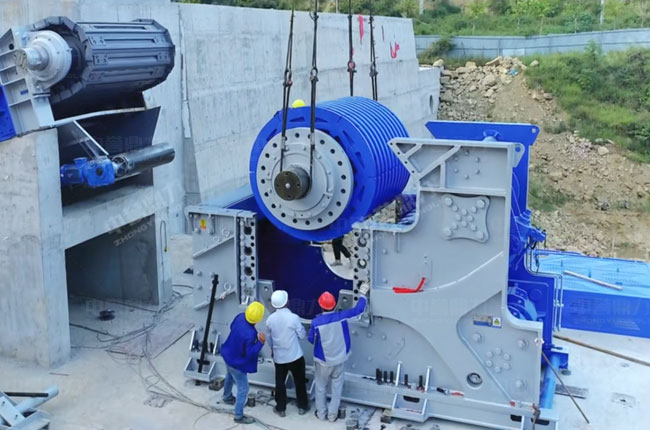

Xinxiang Dingli elaborately designs a kind of special primary hammer crusher that can directly crush the aggregates with particle size of 600mm-1200mm into less than 25mm by absorbing international advanced technology. It crushes the medium hardness and brittle materials with the compress strength less than 200 MPa and calcium content over 40%,such as limestone, coal, salt, chalk, gypsum, alum, brick, tile, coal gangue and so on.

With making circular movement, YK vibrating screen manufactured by Dingli is a multi-level and efficient new vibrating screen, designed specifically for screening material in the quarry, also for product gradation of coal preparation, mineral processing, building materials, electricity and chemical and other industries. The circular vibrating screen has big four types with various sizes. The exciter can be vibration box or eccentric block; the motor can be connected in the mode of universal joint or tire coupling.

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.