Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderPulse bag deduster refers to the device applied in the large sand production line or stone crushing production line.

Dedusting area:60-400㎡

Highest wind capacity: 64000-96000m3

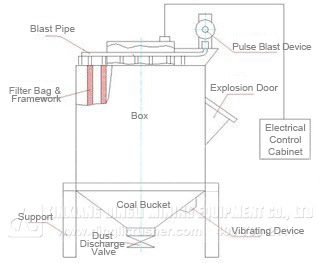

Pulse bag deduster refers to the device applied in the large sand production line or stone crushing production line for collecting the dust and other impurities to improve the cleanness of production environment. In accordance with the working principle, it can be divided into filter dust collector, water mill dust collector, gravity dust collector, etc. According to the type of production and application, it can be divided into the deduster respectively used for metallurgy, mining, cement and building materials. The DMCA mining deduster is especially applied in mining production.

DMCA pulse bag deduster is specially used for dust removal in the mining industry. Lots of dedusting equipment is configured in various sand production lines so as to collect the powder and other impurities in the production line. More dedusters shall be configured in the large production projects to greatly purify the production environment.

The operation process of DMCA pulse bag deduster is as follows: the dusty gas enters into the ash hopper through the air inlet. A portion of coarse dust particles fall into the hopper due to inertia or natural subsidence; the remaining air moves into the bag with the rise of air flow. With the dust particles retained on the outside of the bag, the purified gas goes into the upper box body from the interior of filtering bag and is then discharged into the atmosphere from the air exit.

Pulse bag deduster can be configured mainly in the large-scale crushing production lines of cement and gravel.

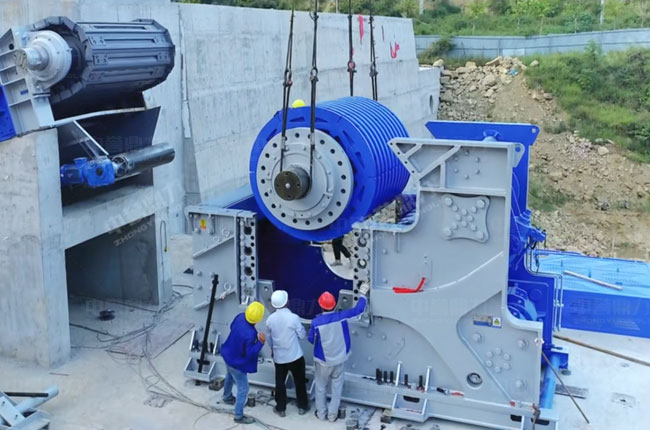

In the following, we briefly introduce how to configure the production line to reduce dust pollution. In the first stage of conveying the aggregates by the vibrating feeder, there is not a lot of dust generated during the process; in the crushing stage of crusher, there is relatively much dust production. ln the process so the deduster, if necessary, can be equipped in the production line so as to greatly reduce the dust pollution; in the final stage when the finished materials with various particle sizes are obtained through the screening of vibrating screen, the dust gas is conveyed upward by the transportation pipeline for being collected. The falling stone powder can be used in a large number of decorative production projects. By fully utilizing various resources in the production line, it can greatly improve the economic benefits of the operators.

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.