Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderMining vibrating screen refers to the mechanical devices used for the screening of various materials in a variety of mine production projects.

Capacity: 70-500t/h

Feed size: ≤150mm

Mining vibrating screen is the equipment mainly used for screening aggregates in the metallurgy, coal, electricity, building materials, electricity and other industries. The aggregates are screened with the screen box moving out of the vibration of exciter. With the advantages of adjustable amplitude, multi-layer screening and high screening efficiency, the vibrating screen is applied for heavy, medium and fine screening. It is also ideal screening equipment for primary crushing, secondary crushing and finished materials.

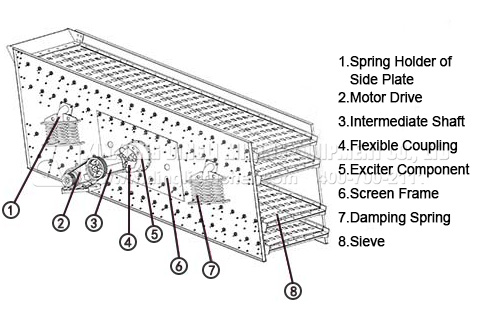

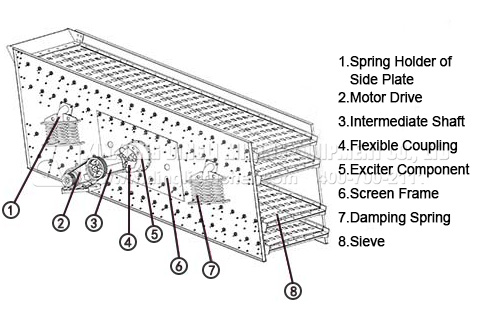

According to the applicable industry and the types of aggregates, the mining vibrating screen can be divided into YKS round vibrating screen, YKZ round vibrating screen, linear vibrating screen and banana screen, etc. The vibrating screen has different types, but its main components and operation principle is the same. It is mainly composed of the motor, exciter, screen plate, sieve, shock damping spring and other spare parts. During the operation, the screen box and surface vibrate under the force of vibrator. The aggregates on the screen surface are loosened and tossed up due to vibration of the surface. The fine-grained material has the opportunity to move to the lower part of the material layer and be screened out through the mesh to complete the process of screening.

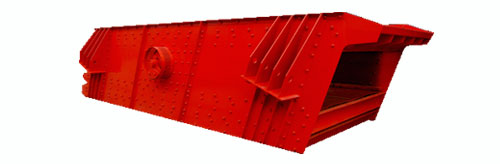

Since the exciter is placed in the upper part of the vibrating screen, YKS circular vibrating screen is also called upper vibrating screen. It is specialized in the mining production. The screening process is completed with the exciter driving the screen surface to move in a circular trajectory. Specially designed for screening the stone in quarry, it has lots of advantages with simple structure, easy maintenance and low power consumption for aggregates screening compared with the middle vibrating screen. As for the appearance comparison with YKZ vibrating screen, we can see the exciter of YKS circular is installed on the upper location of vibrating screen.

YKZ circular vibrating screen equipment is also known as middle vibrating screen with its exciter being placed in the middle of the vibrating screen. It is designed especially for screening the stone in quarry. Its operation principle is almost as the same as that of YKS vibrating screen with making movement in a circular trajectory. However, it has some different features compared with YKS vibrating screen; for example, YKZ circular vibrating screen adopts riveted structure without welding stress. It also has the characteristics of long use life, high capacity, high screening quality and screening efficiency. From the outside appearance, it can be seen that the exciter is installed in the middle of the vibrating screen, which is distinguished from the upper vibrating screen.

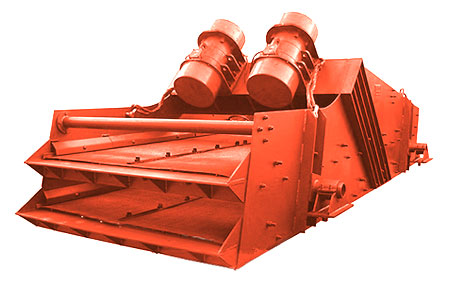

Linear vibrating screen is common material screening equipment in the mining production with dual-vibration motor as vibration source. Under the action of exciting force of vibration motor, the screen body is forced to drive the sieve to make a linear trajectory with the aggregates on the surface are cyclically tossed up forward for screening. It is widely used for wet & dry classification and dehydration of medium and fine aggregates in coal, metallurgy, light industry and other industries. Compared to the circular vibrating screen, the device can carry out finer screening of dry powder or granular materials.

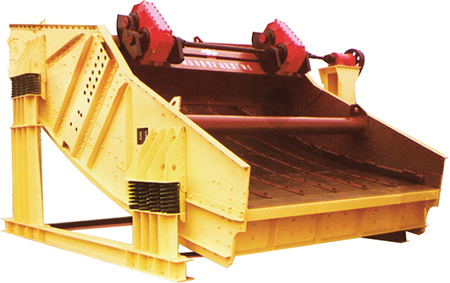

Banana screen is a large and medium-sized screening machine with large screening capacity. It is mainly composed of screen box, screen, exciter, damping spring and lower seat frame. As for the operation principle, the exciter, serving as vibration source, drives the screen box to move in the approximate elliptical trajectory, meanwhile, with relatively large angle of screen surface, the aggregates on the sieve move quickly forward and loose for completing the screening process. It is suitable for screening sinter ore, coal, limestone, broken stone, gravel, metal or nonmetallic ore and other materials. It is widely used in metallurgy, coal, building materials, refractory materials and other industries.

The main components of mining vibrating screen include motor, exciter, screen plate, sieve, damping spring and other spare parts. With China’s increasing emphasis on environmental protection, a variety of dust-proof devices will also be equipped to reduce the dust generated in the screening.

The general production process is as follows: with the exciter vibrating under the driving of motor, the aggregates on the sieve starts to vibrate for being conveyed to the next-level production equipment or the silo. According to the particle size of finished material, the corresponding mesh is selected for screening out the aggregates. The sieves with different sizes are needed to meet the requirements of the project scale.

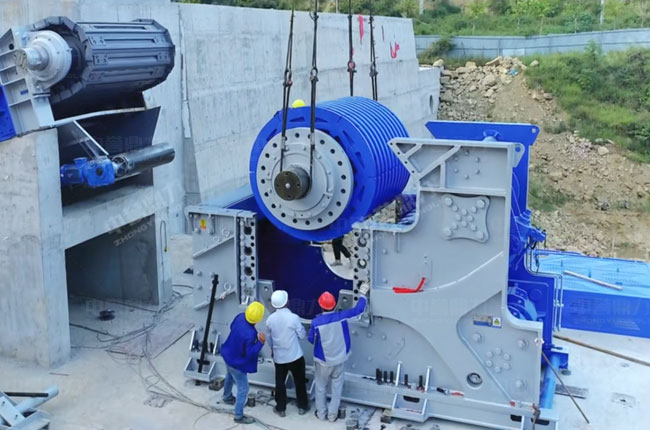

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.