Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

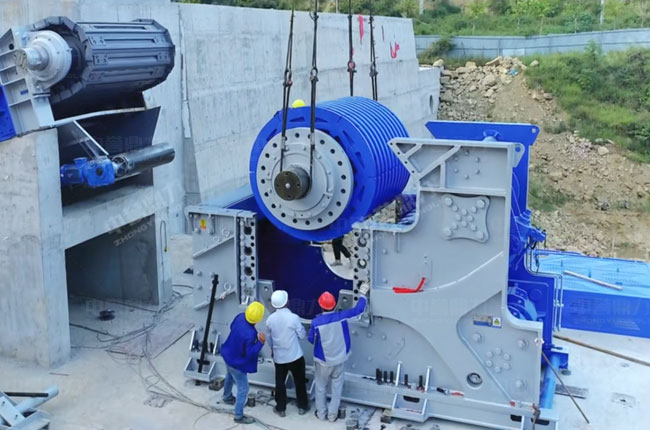

Sand Aggregate IndustryComprehensive Service ProviderQuarry equipment refers to a variety of equipment used in the production of stone plants, including ore mining equipment, ore washer and crusher.

Capacity: 50-30,000TPD

Application:bluestone,limestone

Quarry equipment refers to the machine specialized in production of finished materials with limestone or other rocks as raw materials in the stone quarries or crusher plants. High-quality quarry equipment can ensure the quality of finished materials, greatly expanding the economic benefits of production. Tested by the market, heavy hammer crusher is the best choice among diverse quarry crushing equipment due to its large capacity and reliable performance.

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.