Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

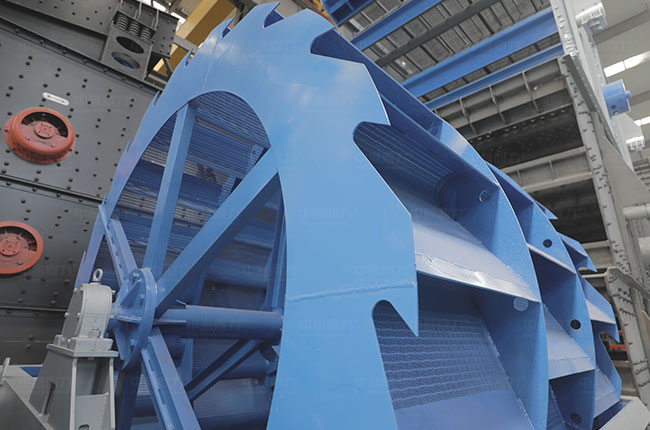

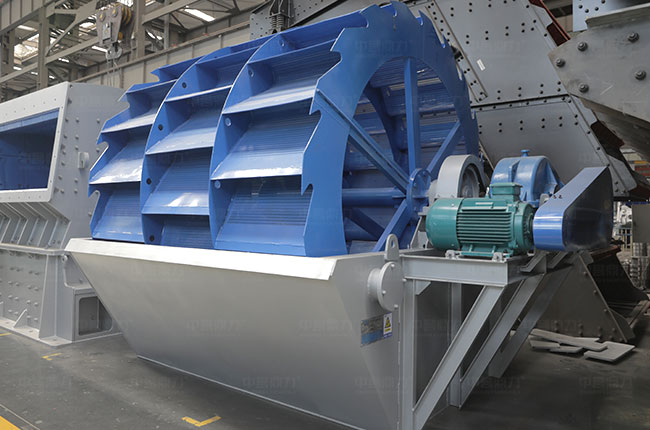

Sand Aggregate IndustryComprehensive Service ProviderThe XS series sand washing machine has the functions of cleaning, dehydration and classification. It is used to wash the soil and dust in the sand in the sand making process to achieve the purpose of cleaning the sand and the output is as high as 600t/h.

When the sand washing machine works, the motor drives the impeller to rotate slowly after decelerating through the triangle belt, reducer and gear. The sand and stone enter the washing tank from the feeding tank, roll under the drive of the impeller, and grind each other to remove the impurities covering the surface of the sand and stone, and destroy the water vapor layer covering the sand and sand, so as to facilitate dehydration; At the same time, add water to form a strong water flow, timely take away impurities and foreign bodies with small proportion, and discharge from the overflow outlet washing tank to complete the cleaning effect. Clean sand and stone are taken away by the blade, and then the sand and stone are poured into the discharge trough from the rotating impeller to complete the cleaning function of the sand and stone.

New sealing structure, and the transmission device sealed, avoid bearing flooding damage, prolong the service life;

Simple structure, in addition to the screen almost no wearing parts, maintenance costs;

Compared with the traditional machinery, the processing technology is more stable.

The machine-made sand treated by the wheel sand washing machine has a rounded shape, which can better meet the requirements of "building sand".

The XS series sand washing machine impeller drive bearing device is isolated from water and water materials, and separates sand and water with high precision, which greatly avoids the phenomenon of bearing damage caused by water immersion, sand and pollutants. Compared with traditional machinery, the failure rate is lower, which is the choice of upgrading in the internal sand industry.

Reasonable structure, novel sealing structure, closed oil valley type transmission device, adjustable overflow weir plate, this series of products, cleaning, dehydration effect is good, fine grain products maintain stability

Simple and reliable

Simple and reliable Environmental protection

Environmental protection Long service life

Long service life Less sand washing loss

Less sand washing lossTechnical Parameters of Sand Washer

| Model | Impellerdia (mm) | Feedingsize (mm) | Power (kw) | Capacity (t/h) | Dimension (mm) |

|---|---|---|---|---|---|

| DLXS2615 | 2600*1500 | ≤10 | 4kw-8 | 30-80 | 3146*2459*2670 |

| DLXS3016 | 3000*1600 | ≤10 | 7.5kw-8 | 80-160 | 3515*2617*3101 |

Note: specifications are subject to change without notice. Please refer to the actual data of machine.

Free consultation on related issues.