Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

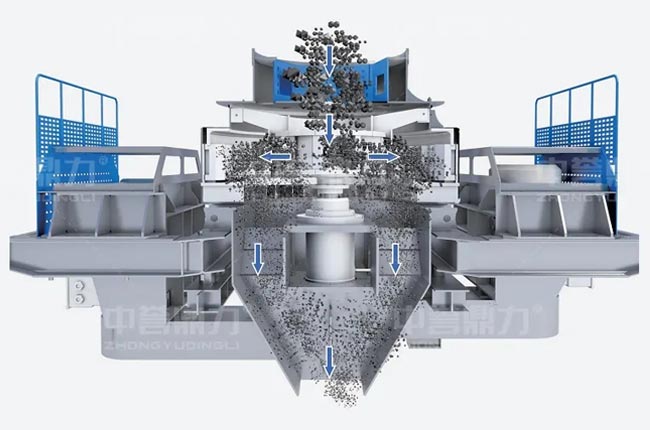

Sand Aggregate IndustryComprehensive Service ProviderVSI vertical shaft impact system sand machine compared with other types of sand making machine, its higher yield and broader applicable materials, can produce mechanism sand, can also be used to beautify the shape of the rubble.

The rotor of VSI vertical shaft impact sand making machine adopts deep cavity design, which can pass more materials. The throughput can reach 580 tons/hour, and the output is 30% higher than that of traditional equipment. At the same time, there are more opportunities for the material to be broken in the crushing chamber. The finished material particle shape is cubic, the material particle shape is good, the gradation is reasonable, and the fineness modulus is adjustable.

The VSI impact sand maker mainly uses a vertical shaft driven by a belt to rotate flat parts equipped with vertical guides. In the process of rotation, the material enters the chamber from the hopper, and is divided into two parts by the separator. One part enters the high-speed rotating impeller from the middle of the separator of the impact sand making machine, is rapidly accelerated in the impeller, and then is thrown out from the three evenly distributed runner of the impeller at the speed of 60-70 m/s. The first part of the material is broken by the self-collecting and falling around the separator. Then it impacts to the material lining in the vortex branch chamber, is bounced by the material lining, impacts to the top of the vortex chamber oblique upward, and changes its direction of movement, deflects downward movement, and the material emitted from the impeller runner forms a continuous material screen. Such a piece of material is subjected to two or more chances of impact, friction and grinding crushing in the eddy crushing chamber. The broken material is discharged from the lower discharge port.

The impact Angle of the crushing chamber is reasonable, the friction between materials and parts is small, and the use cost of the equipment is direct; The structure of rotor components is optimized and the cost is lower. Combined hammer design, can be replaced according to the wear condition of individual hammer, later parts replacement cost.

The use of thin oil lubrication, to solve the bearing heating and other problems, so that the spindle bearing to maintain a constant temperature state, equipment work more, equipped with air cooling and heating system, PLC intelligent system for equipment lubrication automatic control, to provide reliable guarantee for the operation of equipment.

Long service life

Long service life Select material good

Select material good Convenient maintenance

Convenient maintenance Pollution is small

Pollution is small

Technical Parameters of VSI Sand Making Machine:

| Model | Capacity(t/h) | Max Feed Size(mm) | Rotation speed (r/min) | Power (kw) | Machine Size L×W×H(mm) | ||

|---|---|---|---|---|---|---|---|

| Crushing | Re-Shaping | Crushing | Re-Shaping | ||||

| DLVSI1263 | 400-480 | 500-580 | <50 | <60 | 900-1300 | 2×315 | 5600x2990x4190 |

| DLVSI1150 | 300-380 | 380-440 | <45 | <55 | 1000-1300 | 2×250 | 5600x2990x4190 |

| DLVSI1145 | 280-350 | 350-400 | <45 | <55 | 1000-1300 | 2×220 | 5600x2990x4190 |

| DLVSI1140 | 250-280 | 300-340 | <40 | <50 | 1100-1400 | 2×200 | 5600x2990x4190 |

| DLVSI20100R | 700-1000(Center feed) | <200 | 1000 | 2×400 or 2×500 | / | ||

Lubricating the technical parameters of the hydraulic pressure station

| Flow rate(L/min) | 8(mm) |

| Double oil pump motor power | 2x0.37 |

| Security protection | Dual oil pumps complementary fuel supply; No oil flow, no oil pressure automatic stop; Water cooling; Winter motor heating start. |

| Dimension L×W×H(mm) | 820x520x1270 |

| Power of mailbox heater | 2 |

Note: specifications are subject to change without notice. Please refer to the actual data of machine.

Free consultation on related issues.