Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

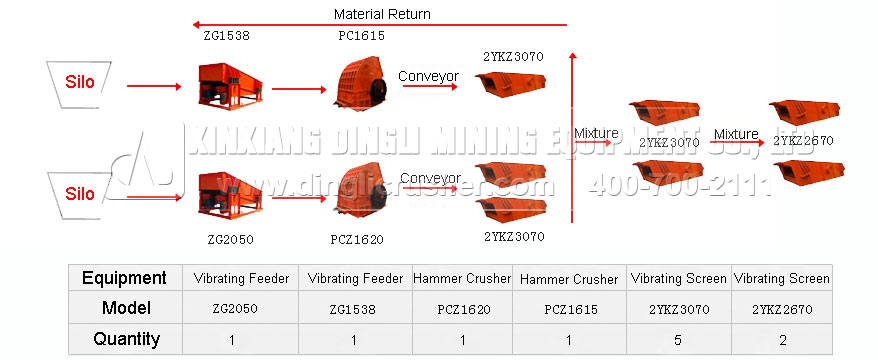

Sand Aggregate IndustryComprehensive Service ProviderXinxiang Dingli Mining Equipment Industry has hammer crusher, vibrating feeder and vibrating screen with high performance and capacity.

Capacity: 50-2500t/h

Application: rigid and friable material

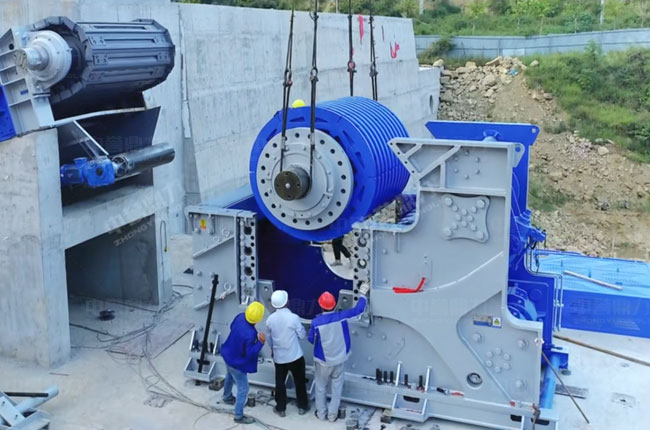

Different from heavy hammer crusher, hammer crusher with letter of PC is a standard crusher with lower output and crushes materials less than 200Mpa hardness as limestone and bluestone. Motivated by electric motor, the hammerhead can crush new aggregates by 360 degree rotating and is widely used in cement and concrete material crushing production line.

By using high speed rotating hammerhead to impact ore, hammer crusher can crush them with its natural fracture and joint surfaces. As ore is fed into crushing chamber, it is crushed by high speed rotating hammerhead. Meanwhile ore gains kinetic energy in the process of impacting and gets into secondary crushing stage by rushing into crushing liner in high speed; meanwhile, ores are also crushed by each other in this process. And then aggregates are discharged from outlet after getting numerous times of crushing.

| Model |

Rotor Diameter Length(mm) |

Feed Opening Width*Length(mm) | Feed Size(mm) | Capacity(t/h) | Power(kw) |

Machine Size Length*Width*Height(mm) |

|---|---|---|---|---|---|---|

| PCZ1308-Ⅱ | 1310×790 | 850×800 | ≤600 | 100-160 | 132 | 2818×2100×2390 |

| PCZ1510-Ⅴ | 1500×950 | 1000×900 | ≤700 | 160-210 | 132×2 | 3260×2414×2750 |

| PCZ1512-Ⅴ | 1500×1160 | 1200×900 | ≤750 | 250-320 | 160×2 | 3260×2624×2750 |

| PCZ1615-Ⅵ | 1650×1452 | 1500×1200 | ≤1000 | 420-500 | 200×2 | 3456×2915×3185 |

| PCZ1620-Ⅱ | 1660×1900 | 2000×1200 | ≤1200 | 800-1000 | 400×2 | 3500×3100×3200 |

| PCZ1820 | 1800×1964 | 2000×1200 | ≤1200 | 1000-1200 | 450×2 | 3270×3210×3520 |

| PCZ2125 | 2100×2486 | 2600×1690 | ≤1600 | 2000-2500 | 1250 | 3728×4565×4667 |

| Moddel |

Rotor Diameter Length(mm) |

Feed Opening Width*Length(mm) | Feed Size(mm) | Capacity(t/h) | Power(kw) |

Machine Size Length*Width*Height(mm) |

|---|---|---|---|---|---|---|

| PC-0706 | 700×570 | 618×510 | ≤400 | 50-70 | 75 | 1950×1340×1480 |

| PC-0808 | 800×750 | 780×610 | ≤500 | 80-100 | 132 | 2280×1790×1670 |

| PC-0910 | 900×1000 | 1070×750 | ≤600 | 150-200 | 110×2 | 2600×2200×1940 |

| PC-1012 | 1000×1180 | 1255×810 | ≤650 | 250-300 | 132×2 | 2800×2310×2210 |

| PC-1213 | 1200×1280 | 1350×900 | ≤750 | 300-350 | 160×2 | 2970×2580×2510 |

| PC-1216 | 1270×1490 | 1530×920 | ≤750 | 400-500 | 200×2 | 3070×2840×2580 |

| PC-1220 | 1220×1950 | 2000×900 | ≤750 | 500-600 | 220×2 | 3080×3380×2580 |

So far, there are many types of crushers in market, such as jaw crusher, impact crusher, and heavy hammer crusher. The price of hammer crusher remains moderate and is cheaper than cone crusher. And with complicated structure and maintenance, cone crusher is specifically crushing harder aggregates. As to impact crusher, it can crush medium hardness aggregate while needs jaw crusher to work as a secondary crusher with wholly high investment. Thus it is wise to choose hammer crusher in reducing investment cost.

With the influence of many outer elements of steel price, human operation costs and the upgrading of technology, the price of hammer crusher cannot keep unchanging. However as a professional hammer crushing manufacturing company, Xinxiang Dingli is keeping providing customers with the most quality equipment in the most reasonable price. If you want to ask the price of the equipment, please inquire professional technicians who can tell you the quotaion after selecting equipment and planning complete production line for you.

To ensure equipment has the best working condition and customer's trust and satisfaction, our company provides customer with qualified accessory and trained maintenance staff to provide prompt and fine after-sale service. Specific after-sale service contents are as following:

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.