Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderFeeder, motivated by energy motor, is used for feeding the aggregates into certain device.

Capacity: 80-800t/h

Feed size: ≤1200mm

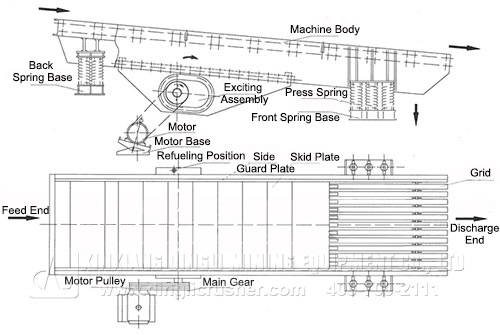

Researched and developed by our company based on years of production experience, the vibrating feeder, also known as feeding machine, is a new generation of feeder which is directly installed under the silo. The series of vibrating feeder with the silo has excellent performance of no blocked or stricken material. There are two types of machines including soil leakage and non-soil leakage. With a smooth vibration, reliable operation, low production costs and labor intensity condition, the feeder serves as the ideal equipment for continuous and uniform feeding to the primary crusher.

Vibration feeder is newly advanced feeding equipment. It is our mission to manufacture energy-saving and environmental protection equipment with the features as follows:

ZGC vibrating feeder is mainly composed of vibrating frame, spring, vibrator, motor vibration frame and motor. When the two vibrating motors rotate synchronously in the opposite direction, the exciting forces generated by the eccentric blocks cancel each other in the X direction and combine together in the Y direction, forming a reciprocating exciting force in the Y direction to cause the feeder to vibrate in a reciprocating linear trajectory. The stepless adjustment of exciting force can be achieved by simply adjusting the eccentric block on the outer side of the two ends. With a certain angle being formed in the inner eccentric block by simply adjusting the eccentric block on the outer side of the two ends, it can achieve stepless adjustment of exciting force and free change & control of feeder flow. As the excitation source, the eccentric block has the features of low noise, low power consumption, sound regulation performance and no blocked material.

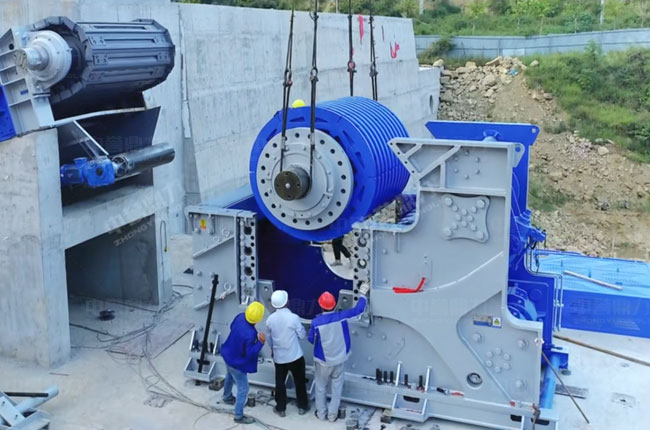

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.