Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderThe vibrating screen is specially applied in the stone plant. It can also be used for screening the products in beneficiation, building material.

Model: YKS, YKZ Series

Application: screen and grade

As the equipment making circular trajectory, the vibrating screen is specially applied in the stone plant. It can also be used for screening the products in beneficiation, building material, electricity and chemistry industries. Its amplitude is adjusted by the eccentric and exciter. Quality spring is used as damping device so as to reduce the impact against vibrating screen.

The vibrating screen of Dingli is mainly in the industry of mining industry. It can be divided into YKS and YKZ two series. As a new efficient vibrating screen with multi layers, it can adjust the amplitude by changing the number of eccentric blocks. Our vibrating screen is featured by simple structure, strong exciting force, high efficiency, small noise, easy maintenance and operation.

YKS series is also called upper vibrating screen. With the vibrator installed in the upper place, it is generally used for screening three or less types of material in the small gravel production line with low price.

YKS series is also called middle vibrating screen. With the amplitude adjusted by the exciter of eccentric shaft and eccentric blocks, it generally screens five types of fine gravel. Featured by simple structure and high efficiency, it is especially favored by large gravel production lines.

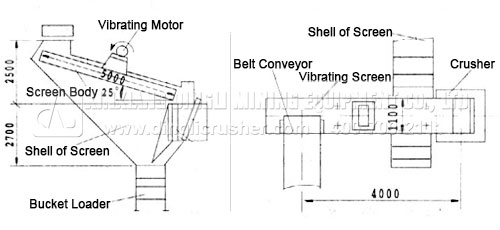

By conveying the crushed material to the sieve through the belt, the circular vibrating screen is applied for fine screening dry and wet material with the features of high efficiency, steady operation and low noise.

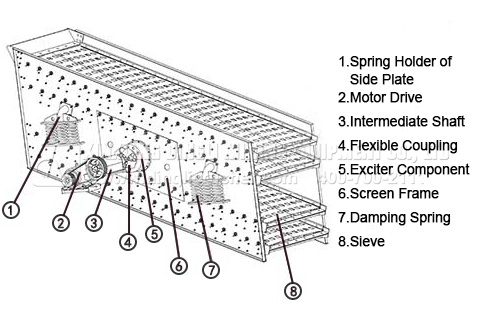

Driven by the motor through the universal joint or tire coupling, the main shaft of YKS vibrating screen rotates at a high speed. With the rotation of main shaft, the vibration box with eccentric block generates a centrifugal inertia force so that the screen box which can vibrate freely will produce the vibration of approximate circular track, completing the screening operation.

YKZ circular vibrating screen generates vibration with the single motor driving the two sets of exciters inlaid the frame to rotate through a flexible coupling. The screen frame is made through riveting of the side plate, channel steel, round tube beam and doubler plate. With the screen surface making round vibration, the aggregates on the sieve constantly reverse and loose. In the process of production, the amplitude can be easily controlled by adjusting the number of eccentric blocks of exciter.

Circular vibrating screen has a single axis. Screen box and screen surface produce a circular trajectory under the action of vibrator. With vibration of the screen surface, the material is loosened and flung away. The fine particles thus move to the lower part of the material layer and are discharged through the sieve. Driven by the motor through the universal joint or tire coupling, the main shaft rotates at a high speed. The vibrating box with eccentric block is mounted on the main shaft and rotates with the spindle to produce the centrifugal inertia force. The screen box is forced to make continuous circular movement while the aggregates are continuously thrown with the screen box on the inclined screen surface. With continuous flip and loose, the aggregates stuck in the sieve jump out to prevent the sieve plug. Such cycles of granularity complete the classification and screening process. Circular vibrating screen has double-amplitude adjustable within 4-7mm depending on the thickness of eccentric blocks.

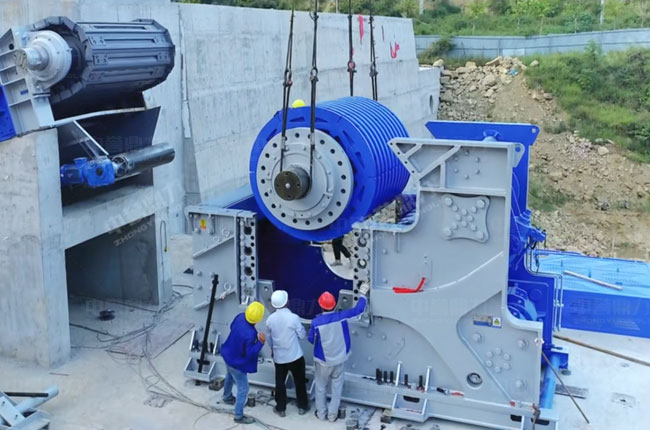

In 2014, we also configured a 1500t/h large stone production line for the customer in Huaibei, Anhui. In order to meet the local needs of huge amount of sand and gravel, we adopt 9 sets of 3YKZ3070 circular vibrating screen which are divided into three groups for screening materials.

In 2014, we configured a 1000t/h large stone production line for the customer in Xingyang, Henan. The selected equipment includes PCZ-1615 heavy hammer crusher, vibrating feeder, 3YKZ3070 vibrating screen *2, 2YKZ3070 *2, conveyor belt, deduster and other ancillary equipment. The highlight of such production line lies in the side-by-side screening of two screens, which could not only increase the output but also screen the aggregates more accurately.

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.