Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderThe stone production line mainly produces stone and finished gravel material. It is generally configured with primary crusher and secondary crusher.

Capacity: customer demand

Max feed size: less than 1.2m

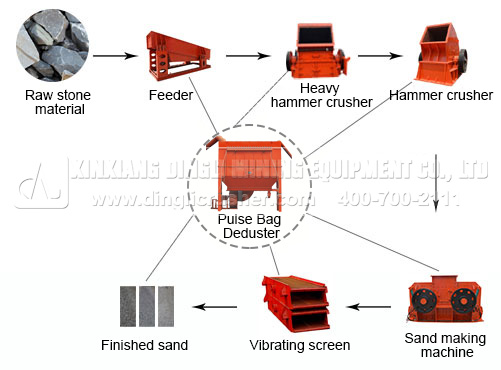

The stone production line mainly produces stone and finished gravel material. It is generally configured with primary crusher and secondary crusher specially for crushing the material with the compressive pressure less than 320Mpa. if the customer has high requirement for the grain shape, one or two sets of shaping machine should also be equipped.

The configuration is generally composed of vibrating feeder, crusher, secondary crusher, vibrating screen and other auxiliary equipment including dedusting and noise-reducing devices, belt conveyor and dust proof equipment. The production project for cement preparation crushing requires more supporting equipment, such as professional deduster in order to reduce air pollution during the production.

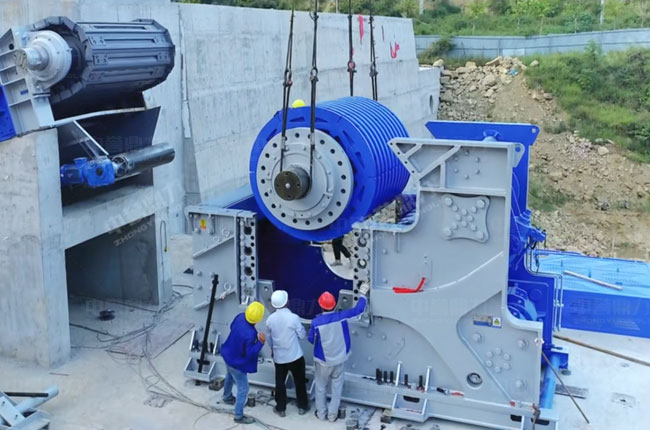

The eco-friendly stone production line designed by Dingli is configured with professional DMCA mining deduster and dust cover in all the production equipment, which greatly reduces the dust pollution of each stage of production. Up to now, we have built many garden-like stone production lines across China.

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.