Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

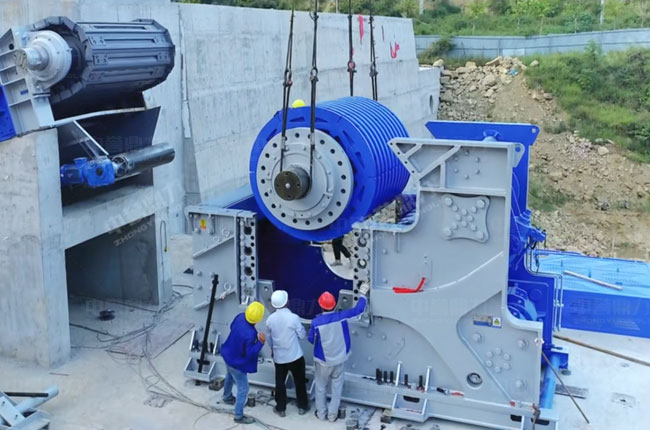

Sand Aggregate IndustryComprehensive Service ProviderHammer mill uses the connection ways of flexible connecting and the motivation ways of co-movement.

Production Capacity: 50-3000tph

Raw Material: limestone

Hammer mill uses the connection ways of flexible connecting and the motivation ways of co-movement. This methods makes the new hammer mill has the features of higher efficiency and energy saving. It is available in building material, chemical, mining, highway, water conservancy, refractory, steel, and so on industries for crushing materials less than 10% moisture and less than 9 Mohs hardness.

The multi-stage grinding ring design reduces the material declining speed, extends material grinding times, and improves finished material quality and production capacity.

The rod and spring connection avoid material damage to machine. And the elastic connection of hammer mill and powder grading machine reduces vibration and noise and improves machine service life.

Vane device with higher density and precision improves the production capacity over 50%. Wind gradation hugely improves machine efficiency. And adjustable vane device improves finished material precision.

Stone crushing plant mainly consists of main machine, high-density beneficiation machine, connection pipe, centrifugal wind machine, dust collector, crusher machine, elevator, silo, vibrating feeder, and electricity control center.

In operation, bulk material is firstly crushed by hammer crusher for expected material size, and then material will be conveyed into silo by elevator or belt conveyor. And then there is vibrating feeder for material conveying into grinding machine or hammer mill for material grinding. And then the grading machine will be used for material selection. Powder and small material will be collected into dust collector and then the finished material will be conveyed into finished material stockpile.

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.