Sand machine, a collective name of sand making equipment, is used for deep processing the raw materials of sand. The proper use of equipment is not only a requirement of production, but also a feasible method to extend the use life of sand machine. The sand machines currently manufactured include heavy hammer crusher, hammer crusher, vertical shaft impact crusher (sand making machine), and ZSJ dual rotor sand shaping machine. They are widely used for primary and fine crushing of limestone, bluestone, shale, river gravel, pebbles, granite, quartz, iron ore, cement clinker and other minerals.

With many years of experience in design and manufacturing of mining equipment and production of sand gravels, Xinxiang Dingli Mining Equipment Co., Ltd has produced a various outstanding machines boasted with advanced technology, simple structure, reliable performance, smooth operation, large crushing ratio, low energy consumption and high output, such as, heavy hammer crusher, hammer crusher, vertical shaft impact crusher (sand making machine), ZSJ dual rotor sand shaping machine. These types of sand machine equipment can crush the oversized materials of 2000 mm into various fine aggregates less than 25mm for only once. With sound grain shape, the materials are well in line with national standards.

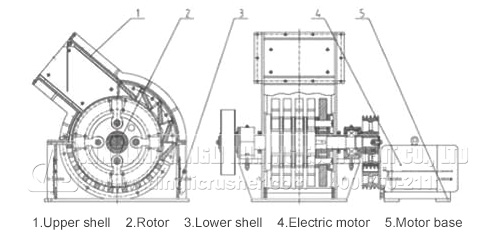

Upgraded on the basis of hammer crusher, the heavy hammer crusher is specially manufactured for artificial sand making with the raw materials of limestone. With the most wear-resistant parts and extra-large feed opening, it can easily crush the bulk materials. The adjustable plate equipped allows the customers to adjust the discharge size according to their needs. Driven by two vertical flanged motors, the vertical shaft impact crusher (sand maker) operates in the principle of “stone striking stone, stone striking iron and iron striking”. With the drive shaft driving the hammers to rotate at high speed, the aggregates in the crushing cavity are crushed by the huge crushing force.

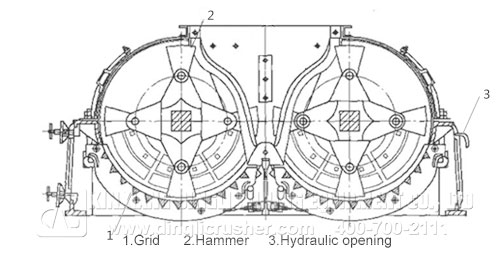

With the two rotors making relative rotation at high speed during the operation of ZSJ dual rotor sand shaping machine, the aggregates in the crushing cavity are hit by the hammers on the first rotor and then crash into the second rotor for being crushed after obtaining certain momentum. Finally the fine sand and gravel will be obtained after the aggregates receive two high-speed strike forces and their particle size of crushing reaches the discharge size of the grid. With the shell adopting hydraulic opening device, it is convenient to conduct regular equipment care and maintenance.

Major equipment: heavy hammer crusher, vibrating feeder, circular vibrating screen, sand making machine, sand washer, conveyors and deduster and other ancillary equipment.

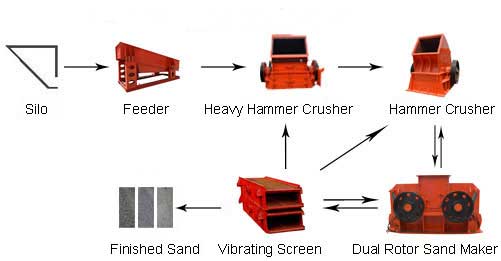

Production process: secondary crushing shall be needed in the production line for the aggregates with high hardness. The general process is: vibrating feeder → feed the heavy hammer crusher (primary crushing) and crush the aggregates for the first time → hammer crusher (secondary crusher) for crushing more standard material → grade the aggregates by YKZ Series Circular Vibrating Screen → send the aggregates suitable for sand making into ZSJ dual rotor sand shaper (sand machine) → screen the finished materials by YKS series circular vibrating screen.

The crushing production line only equipped with primary crusher is applied to the aggregates with the compressive strength less than 200Mpa and calcium content higher than 40%. The general process is: vibration feeder for feeding→ heavy hammer crusher for crushing bulk materials→ conveyor the crushed materials directly into ZSJ sand shaping machine (sand machine, used for aggregates shaping and crushing) → circular vibrating screen for screening → finished materials.

With continuous advancement of technology, the sand machines are upgraded from generation to generation. By introducing two outstanding results in the manufacturing industry of sand making machine and developing six patents with independent intellectual property rights, Dingli has dramatically solve the drawbacks of single-rotor sand maker, which consumes high dynamic energy and produces the stones with poor shape. The impact sand maker produces the stones with sound shape but consumes high dynamic energy. Dingli’s ZSJ sand maker especially improves the historical disadvantage of low capacity and high dynamic energy consumption of the single machine in the sand making industry.

Sand machine, collective name of sand making equipment, is used for deep processing the raw materials of sand.

300TPH Stone Production Line in Handan Hebei

300TPH Stone Production Line in Handan Hebei 1500TPH Stone Production Line in Leiming Mining Plant

1500TPH Stone Production Line in Leiming Mining Plant 1500TPH Limetone Production Line in Sichuan

1500TPH Limetone Production Line in Sichuan 500-800TPH Gravel Crushing Project of Shiyu Concrete Company

500-800TPH Gravel Crushing Project of Shiyu Concrete Company 1500TPH Stone Production Line in Guangxi

1500TPH Stone Production Line in Guangxi 200-250TPH Sand Making System of Zoomlion in Anyang

200-250TPH Sand Making System of Zoomlion in Anyang 700TPH Fluorite Production Line in Jiujiang

700TPH Fluorite Production Line in Jiujiang 200TPH Stone Plant in Baoan County Daye Hubei

200TPH Stone Plant in Baoan County Daye Hubei