Method on Stone Sand Machine Maintenance

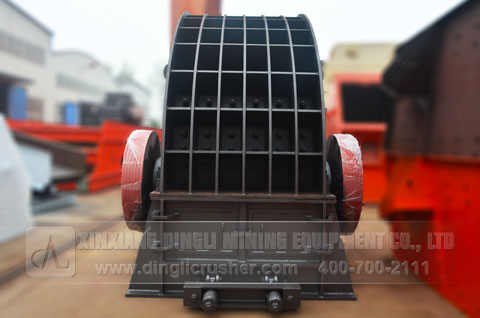

Stone machine has hammer sand machine, impact sand machine, jaw sand machine, impact sand machine with different working principle and structures. Hammer sand machine is available in medium hardness material of limestone. As we all know, with detailed maintenance, machine can have a fine production and work. Next, we will introduce you the hammer crusher maintaining tips for better machine using.

Hammer stone machine mainly crushes material with impact force. Materials are firstly fed into crushing chamber and then they are crushed by hammerhead, impact liner, and materials. The qualified material will be discharged from the seive. Hammer sand machine has high working strength, lower trouble, and higher service life with regular maintenance.

1. Machine checking. Check related bolts loosen condition and wear condition for timely maintenance and changing.

2. Timely oil adding with once in three months. There are lubrication oil and grease. Lubrication oil always be used in clean place and lubrication grease has higher sealing condition in dirty place.

3. Clean machine chamber after stopping operation and remove other material and clogging material.

4. Regular check wear condition of hammerhead and liner.

5. Average and continuous material feeding, in case of machine breakdown.

6. Regular checking of rotor to extend machine service life, reduce machine trouble, and improve machine using rates and output.

More

- The Price of a Set of Sand Machine

- Location of Limestone Sand Machine

- Tips of Dingli Stone Sand Maker with Fine Material Shape

- Failure&Maintenance in Sand Machine Operation

- Location of Limestone Sand Machine

- The Price of a Set of Sand Machine

- Influencing Elements of Sand Machine Price

NextContent:none