Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderYK series circular vibrating screen is our company design for stone screening of new products, is a multiple layers, high screening efficiency of vibrating screen.

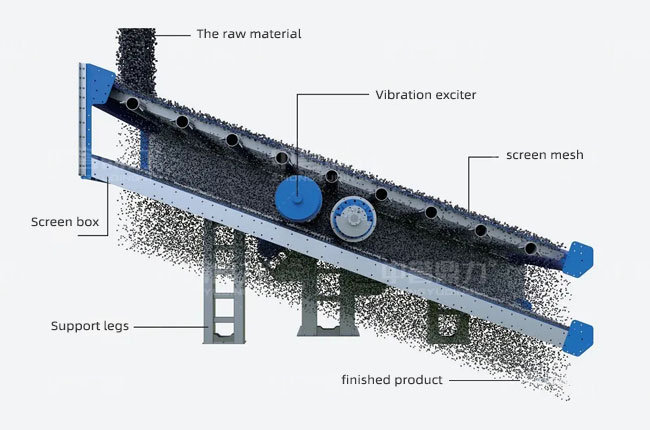

The screen machine is mainly composed of a screen box, a screen frame, a screen mesh, a vibration motor, a motor base, damping springs, and supports. Linear vibrating screen uses double vibration motor to drive. When the two vibration motors synchronize reverse rotation, the eccentric blocks generate a vibration force parallel to the axis of the motor. The forces offset each other in a direction perpendicular to the motor shaft and stack as a resultant force, causing the motion track of the screen machine to be linear. The two motor shafts create a dip angle relative to the screen surface. The combined force of vibration and gravity causes materials to be thrown up onto the screen surface for linear motion, achieving the purpose of material screening and classification.

The equipment has a small size, light weight, simple and compact structure,requires little maintenance, and has low operating costs.

Due to the high fluidity of the rock material, channel blockage is reduced, resulting in a large ore drawing capacity, high efficiency, and less power consumption. This leads to significant energy savings.

The electrical control adopts a half-wave rectifier, which allows for stepless adjustment of the feeding amount. This enables automatic production control and facilitates the automation of the production process.

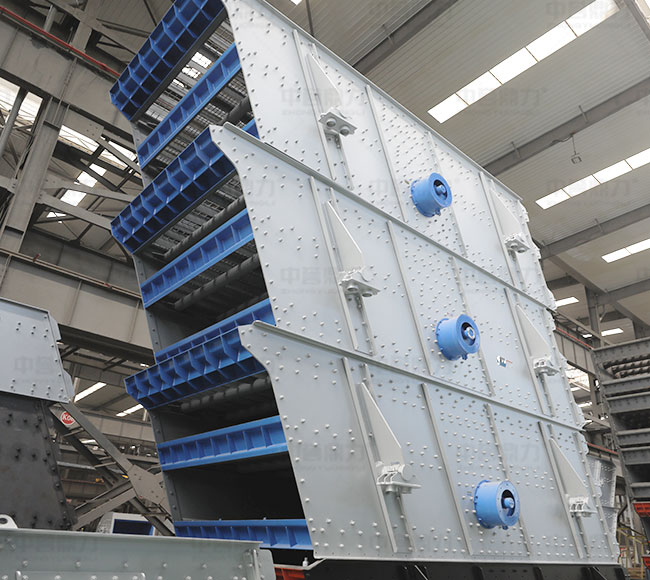

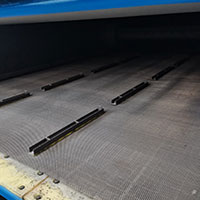

The screen mesh can install with more than four layers of different aperture sizes allows for the simultaneous production of five finished materials with varying specifications.

The vibrating screen body is milled on both sides using a Gantry-type Milling Machine, with holes drilled. The vibration exciter is assembled with a horizontal center through this process, and flexible bearings are used to flexibly connect with the motor, resulting in low motor impact and stable operation.and work can be carried out continuously with uniform vibration flow that is easy to control. The size of ore flow can be adjusted according to needs, ensuring safe and reliable operation.

Working in a resonant state, the amplitude remains stable, allowing for significant fluctuations in load on the shaking table. This is due to the strong adaptability of various mineral rock materials and their ability to function effectively in dusty or wet working environments.The material tank made of alloy steel plate is suitable for conveying high temperature, serious wear and corrosive materials.

Amplitude modulation

Amplitude modulation Long service life

Long service life Run smoothly

Run smoothly Convenient maintenance

Convenient maintenance

Technical Parameters of Middle Vibrating Screen

| Model | Number of deck | Exciter | Screen Area (㎡) | Inclination (°) | amplitude (mm) | Capacity (t/h) | Power (kw-6) |

|---|---|---|---|---|---|---|---|

| DL2YKZ2060 | 2 | JF150 | 14.4 | 24 | 6-8 | 60-350 | 30 |

| DL2YKZ2470 | 2 | JF150 | 16.8 | 24 | 6-8 | 60-350 | 45 |

| DL2YKZ2670 | 2 | JF150 | 18.2 | 24 | 6-8 | 80-450 | 45 |

| DL2YKZ3070 | 2 | JF150 | 21 | 24 | 6-8 | 100-600 | 45 |

| DL2YKZ3080 | 2 | JF200 | 24 | 24 | 6-8 | 100-600 | 45 |

| DL2YKZ3680 | 2 | JF200 | 28.8 | 25 | 6-8 | 200-900 | 90 |

| DL3YKZ2460 | 3 | JF200 | 14.4 | 24 | 6-8 | 60-300 | 45 |

| DL3YKZ2470 | 3 | JF200 | 16.8 | 24 | 6-8 | 60-300 | 55 |

| DL3YKZ2670 | 3 | JF200 | 18.2 | 24 | 6-8 | 80-400 | 75 |

| DL3YKZ3070 | 3 | JF200 | 21 | 24 | 6-8 | 100-500 | 75 |

| DL3YKZ3080 | 3 | JF200*2 | 24 | 24 | 6-8 | 100-500 | 75 |

| DL3YKZ3680 | 3 | JF200*2 | 28.8 | 25 | 6-8 | 200-800 | 75*2 |

Note: specifications are subject to change without notice. Please refer to the actual data of machine.

Free consultation on related issues.