Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderSingle-stage hammer crusher, also called single-rotor hammer crusher, is applied to crush brittle ore like limestone, muddy siltstone, shale, gypsum.

Feed Size:≤1200mm

Output:80-1000t/h

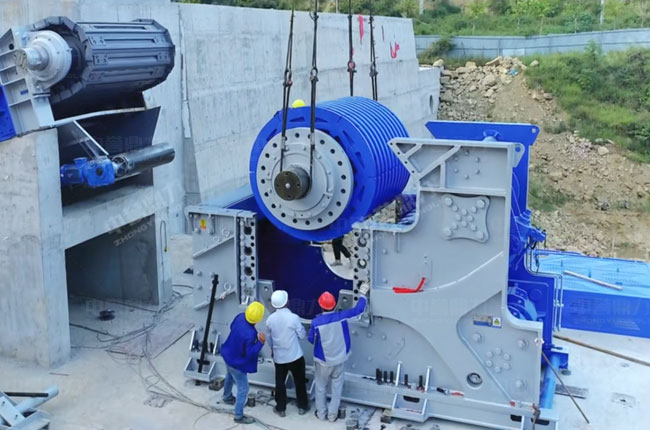

Single-stage hammer crusher is especially manufactured for preparing cement and crushing limestone & clay mixture. With reasonable design of rotor and suitable machine size, it can fully crush the material into required size for only once. Therefore, it is an economical and reliable solution to select DPC single-stage hammer crusher for the large crushing project.

DPC single-stage hammer crusher is the main product of Dingli. It is mainly used for cement preparation and gravel production in the large projects. The applicable material includes limestone, muddy siltstone, shale, gypsum, coal and other with compressive strength less than 150Mpa.

Single-stage hammer crusher is mainly composed of rotor, bearing, bear plate, shell and drive device. It uses hammers to strongly hit the stones in the upper cavity. Then the crushed stones will suffer impact of counterattack plate and collision of other stone before they enter into the two symmetric discharge areas and are discharged through the lower crushing cavity formed by the rotor.

| Model | Rotor diameter(mm) | Feeding Opening Width*Length(mm) | Feed Size(mm) | Capacity | Power(kw) | Machine Size Length*Width*Height(mm) |

| DPC1308 | 1310×790 | 850×800 | ≤600 | 100-160 | 132 | 2818×2100×2390 |

| DPC1510 | 1500×900 | 1000×90 | ≤700 | 160-210 | 132×2 | 3260×2414×2750 |

| DPC1512 | 1500×1160 | 1200×900 | ≤750 | 250-320 | 160×2 | 3260×2624×2750 |

| DPC1615 | 1650×1452 | 1500×1200 | ≤1000 | 360-420 | 200×2 | 3456×2915×3185 |

| DPC1620 | 1660×1900 | 2000×1200 | ≤1200 | 500-800 | 315×2 | 3500×3100×3200 |

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.