Introduction about Single-stage Hammer Crusher America

One of the main crushing machines of Dingli single-stage hammer crusher is mainly used in building material and other road and rail way industries. As to crushing materials, it is available in crushing medium hardness with less than 200Mpa compressive strength and more than 40% calcium of limestone. Single-stage hammer crusher can crush stone into demanded material size once, which saves investment cost and reduce technology process.

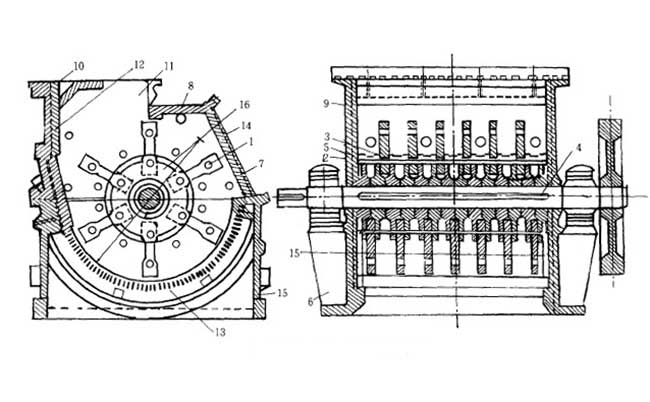

Working principle

It mainly consists of hammerhead, rotor, spindle, disc, and pin. In crushing machine, motor will drive rotor have a high-speed rotating in crushing chamber. After fed into machine, material will be crushed by hammerhead and then the qualified material will be discharged from the sieve placed under the rotor.

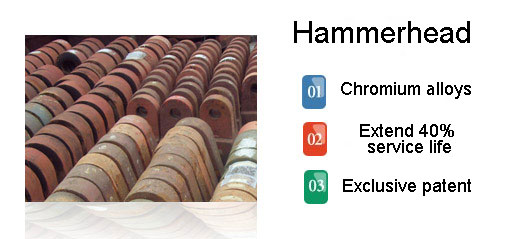

Hammerhead description

Hammerhead texture counts for much in single-stage hammer crusher. High wear-resistant hammerhead with alloyed component material will have five times longer service life and 30% crushing efficiency more than ordinary crusher machine. The main character of alloyed hammerhead is made by double alloy liquid with centrifugal pressure to ensure it have a high wear-resistance. With high wear-resistance condition, this kind of machine receives many praises from cement and mining industries. With that making method, hammerhead can have a longer service life and working efficiency and then can be available in many crushing industries of coal, glass, mining ore, cement limestone, brick, etc.

Advantages

1. Large feeding material and small discharging material

Single-stage hammer crusher of Dingli can crush 1200mm material into less than 75mm materials once.

2. Adjustable discharging material size

The sieve in the gate can control the material size.

3. Stone crushing stone crushing upgrading

With this upgrading, it has higher self-crushing rates and lower hammerhead wear condition and loading.

4. Unique production line and simple production

This machine can crush material into demanded material size once.

Performance feature

1. High strength rotor; the optimized design of rotor is applied with FEA (Finite Element Analysis) for longer using life.

2. World wear-resistant bead welding technology; with WHM high hard surface cladding technology, it has twice longer service life than other welding machine.

3. New sieve design; this design ensure single-stage hammer crusher have a smooth material discharge, fine, average, and stable material size, and longer service life.

Precaution in safe operation

1. Open machine with non-loading. Interlock v-belt conveyor with feeder not crusher for timely stopping and safe operation.

2. Fasten the bolts of machine once a week.

3. Average crusher machine feeding, and remove foreign materials with metal crushing noise.

4. Train workers for machine maintenance and operation. Workers should have a full understanding of machine operation knowledge, machine principle and structure, and operation rule for safe operation.

Contact us for more single-stage hammer crusher information with http://www.dinglicrusher.com/contact/, dingli@dinglicrusher.com, or 400-700-2111.

More

- Single-stage Heavy Hammer Crusher Feasibility Study

- Advantages of Single Shaft Impact Crusher

- Single Hammer Crusher Manufacturer Selection

- Single-stage Hammer Crusher Price Crusher Direct Seller

- Single-stage Hammer Crusher Operation Rule and Maintenance

- Introduction about Single-stage Hammer Crusher America

- Reasons & Solutions of PCD Single-stage Hammer Crusher B

NextContent:none