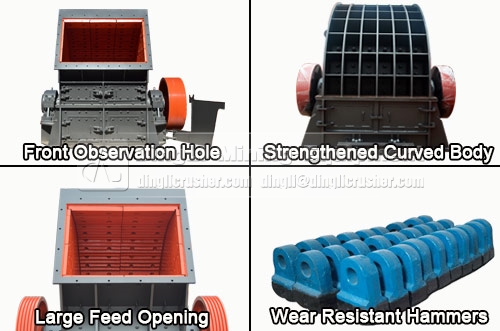

Hammer Crusher Texture Introduction

Release Date:2017-03-24 Edited by:{content:Author}

Hotline: 0086-18336065555

Abstract:Different spare parts need different texture and proper and suitable texture will improve crusher production performance.

Different spare parts need different texture and proper and suitable texture will improve crusher production performance.

Hammerhead texture requirement

Hammerhead should have a higher wear-resistant condition with following character:

Forging hammerhead: by adopting quality train wheel steel of 65Mn, hammerhead has the characteristics of good impact-proof ability, high flexibility, and wear-resistance after being forging into demanded shape and size.

High manganese steel hammerhead: with the texture of Mn13, Mn13Ce2, and Mn18Cr2, hammerhead has high flexibility, excellent technique, low price, and main characteristic of over 5-7times hardness than other materials.

High chrome alloyed steel hammerhead: with high chrome alloyed steel, hammerhead has high wear-resistant condition and is widely used in fine crusher and impact crusher.

Hammerhead of Dingli has multi-elements and with manganese and chrome for higher wear-resistant condition and longer service life over 30%.

Liner texture

Liner installs inside of crusher shell for crushing and squeezing materials. So liner should have higher wear-resistant and impact-proof condition.

The forging technology of Dingli is with transformation, crystallization, and freezing. Therefore, it has higher strength, high impact-proof condition, strong wear-resistant condition, and various applications compared with traditional machines.

Rotor

Rotor is the key spare part of crusher that depends on the quality of machine. The high manganese steel material can hugely improve rotor service life. Also the Mn18 ring beside rotor has higher protection ability than that of jaw crusher and improves machine service life.

PreviousContent:emptyText

NextContent:emptyText

Customers

More

- Hammerhead Type and Hammer Crusher Introduction

- PC-2022 Hammer Crusher Parameter Introduction

- Main Cobble Sand Making Equipment

- Influential Elements on Prolonging Hammerhead Life

- How to Judge Vertical Compound Crusher Company

- Single-stage Heavy Hammer Crusher Feasibility Study

- Heavy Box-type vs. Compound Hammer Crusher

- Hammer Crusher Texture Introduction

- Common Heavy Stone Crushers & Applications

- Comparison and Contrast of Gravel Aggregates Machines