Hammerhead Type and Hammer Crusher Introduction

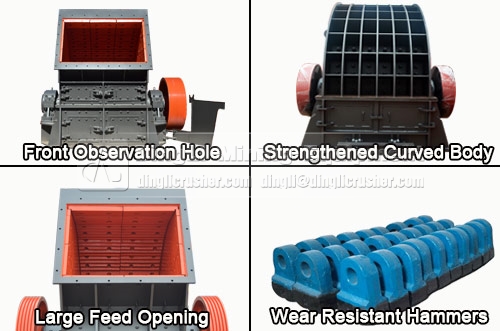

Hammerhead is the main spare parts of hammer crusher. In operation, high-speed rotating rotor drives hammerhead for material crushing.

So far, there are two manufacturing techniques of hammerhead of forging and casting. With the demand of higher wear-resistant hammerhead and flexible handle, using alloyed steel and manganese material and forging and casting methods will be more economical.

There are different hammerhead types of high manganese steel hammerhead, dual metal hammerhead, component hammerhead, and hard alloyed hammerhead with different textures.

Description

1. Forged hammerhead

Forged hammerhead can be used for crushing cobble, coal gangue, limestone, etc. With 65Mn steel, hammerhead has better impact-resistance, strong flexibility, fine wear-resistance, and hard condition. In forging, hammerhead is made by hitting and gets the mechanical performance and the shape and size. And the quenching method can ensure hammerhead have high hardness and wear-resistance.

2. High manganese steel hammerhead

High manganese steel is the common and broad texture. It is always used in wear-resistant parts production for fine flexibility, good technology, and low price. In making hammerhead, the surface will be quickly hardened under huge impact and strain force. So hammerhead has higher wear-resistant condition.

However, high manganese steel hammerhead has higher demand on machine performance feature. In actual operation, machine will have slow hardening with less impact or strain force. Thus, in selecting hammerhead, actual parameter will help you a lot in expending your economic profits.

3. High chrome hammerhead

High chrome material has better hardness and excellent wear-resistant condition. With bas flexibility, some companies upgrade hammer handle with high manganese steel. In this way, it will full extend their advantages and meet using demand. However, this kind of method has higher price, strict technology demand, and complex technique.

4. Hard alloyed hammerhead

Compared with other hammerhead, hard alloyed hammerhead had higher hardness, bending strength, impacting, and heating resistance, and low cost. This texture effectively solves the problems of cracking, desoldering, hakobore, and chipping. After practice, the advantages of hammerhead are as follows.

1. High-wear-resistance

2. Impact resistance.

3. Wide application.

Technology introduction

Hammerhead technique demands its service life. The disadvantages of hammerhead surface will hugely reduce hammerhead performance feature or even break hammerhead. So, Dingli uses suitable forging and heating handle methods for higher performance feature. Such as, control casting heat for cooling order and condition, express chrome advantage with heating handle. All in all, suitable production technology and quality checking methods decide hammerhead using performance.

In conclusion, Henan Dingli Mining Equipment Co., Ltd. has abundant hammerhead types, high wear-resistant performance, low maintenance, and lower cost of money and time in maintenance. More hammerhead information and price can be learned in www.dinglicrusher.com, dingli@dinglicrusher.com, 400-700-2111.

Customers

More

- Single Hammer Crusher Manufacturer Selection

- Single-stage Hammer Crusher Price Crusher Direct Seller

- Major Factors that Affect Grinding Efficiency of Crusher

- Reasons & Solution in Abnormal Hammer Crusher Vibrating

- Influential Elements on Prolonging Hammerhead Life

- Henan Sand Maker Company and Price

- Working Principle & Performance of Dual-Stage Crusher

- Major Factors that Affect Grinding Efficiency of Crusher

- Price of Reversible Hammer Crusher

- How to Lower Down Bearing Failure Rates of VSI Crusher