Influential Elements on Prolonging Hammerhead Life

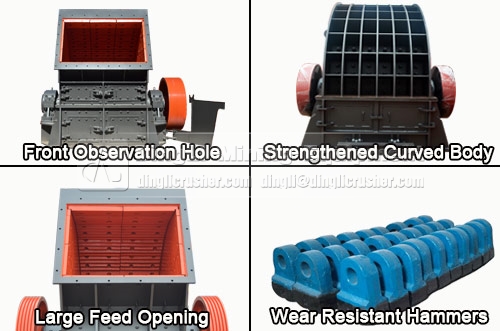

Hammerhead is the core parts of crusher, which holds the major force. In using machine, hammerhead will be abraded and then shortens its life. Fortunately, frequent machine changing will increase machine using life. Then we will analyze the elements of influencing machine using life.

1. Hammerhead texture: the common machine we used is made by high manganese steel, high chrome, alloyed steel, and other materials. However, different materials have different strength and flexibility, so that we should choose suitable machine for high efficiency.

2. Chemical component: the chemical component of high manganese steel is relevant to machine performance and wear. Appropriate hammerhead component and gradation will improve machine quality and prolong machine service life.

3. Structure design: hammerhead design has great influence to the inside organization of machine and its mechanical property. Through analyzing various hammerheads of break and invalidation, Dingli finds the reason of machine break is the mismatching between the inside and surface of machine. So, in producing hammerhead, we should have suitable forging and heat handling.

4. Technical parameter: the technical parameter of hammer crusher which mainly rotor power and rotating speed will influence hammerhead service life. These technical parameters are related to its production capacity and hardenability.

5. Inside gap: hammer crusher inside gap mainly refers to the gap between rotor and impact plate or grid and hammerhead. The gap opening will influence the material clogging condition around grid and emergency exit. More clogging material will abrade hammerhead, thus, you should adjust machine gap for appropriate operation.

6. Crushing material size and hardness: larger material needs higher machine flexibility and higher material hardness demands higher machine and hammerhead hardness. With these demand, we should adopt the suitable machine type with finished material requirement for long machine service life.

Measures in prolonging hammerhead service life

1. Appropriate material feeding size: you should control crushing material size with hammer crusher design type.

2. Suitable hammerhead texture: hammerhead texture is the key element of wear and using life. The common material is high manganese steel and multi-alloyed steel hammerhead.

3. Proper hammerhead shape and space: this is related to hammer plate wear and plate using ratio.

4. Install hammerhead with rule: there should be two protection rings aside main spindle.

5. Suitable hammerhead weight: there should be same hammerhead weight in changing hammerhead for stable operation.

6. Fixed hammerhead: in working, improper hammerhead fixation will arouse hammerhead separating from rotor and then cause machine failure.

7. Suitable rotor power and rotation: this is related to hammerhead hardenability.

8. Regular machine clean: regular clean will extend hammer crusher service life and cause hammerhead wear.

9. Regular hammer crusher changing will extend hammerhead service life.

This is the influential elements of hammerhead and measures on extending service life. In using hammer crusher, proper hammerhead using will reduce hammerhead changing costs. Dingli has the core machine of hammer crusher which is made by high manganese steel. So Dingli crusher has longer service life and lower spare parts costs. Please contact us with e-mail of dingli@dinglicrusher.com.

Customers

More

- Over-all Introduction—Single Stage Hammer Crusher and Price

- Cobble Sand Maker Performance Feature and Advantages

- Hammer Crusher Texture Introduction

- Operation Process Introduction of Dingli Hammer Crusher

- Methods of Quick and Easy Hammerhead Changing

- Introduction of Hammer Crusher Application

- Daily Operation and Maintenance of Hammer Crusher

- Reversible Impact Hammer Crusher for Green Stone Plant

- Cobble Sand Maker Performance Feature and Advantages

- Price of Reversible Hammer Crusher