Working Principle & Performance of Dual-Stage Crusher

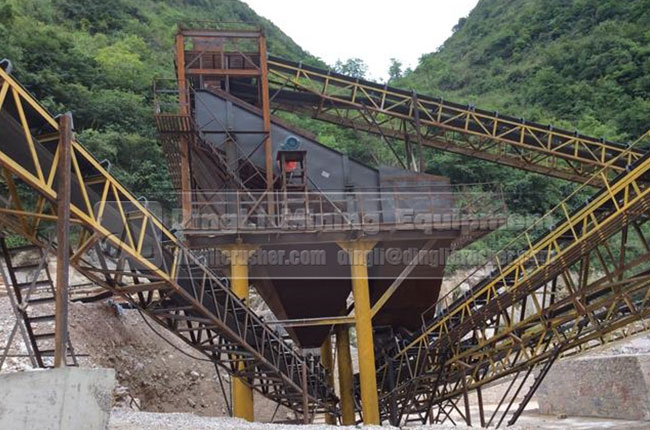

Dual-stage hammer crusher also called impact hammer crusher designed by combining the advantages of hammer crusher and impact crusher. Under the trend of forcing development, this machine is very popular. Then we will introduce you the dual-stage hammer crusher briefly.

Working principle

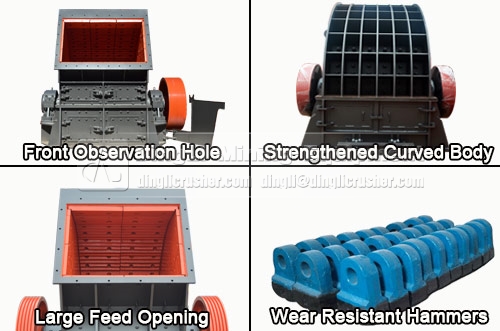

Dual-stage hammer crusher consists of shell, rotor, hammerhead, impact liner, and adjustable liner. Bulk material is fed into the machine and then firstly crushed by high speed rotating hammerhead and then crushed by shell and material themselves, finally they are discharged from machine with demanded material size.

Performance introduction

Customers

More

- Impact Crusher Spare Parts Changing

- Methods to Extend Service Life of Hammer Impact Crusher

- Reasons & Solution in Abnormal Hammer Crusher Vibrating

- PF Impact Crusher Advantages in Stone Production Line

- Models and Features of Counterattack Crusher

- How to Lower Down Bearing Failure Rates of VSI Crusher

- Reversible Impact Hammer Crusher for Green Stone Plant

- Working Principle & Performance of Dual-Stage Crusher

- Wear Resistant Condition of Impact Single Stage Crusher

- Performance Feature Analysis of Hammer Impacting Crusher