Wear Resistant Condition of Impact Single Stage Crusher

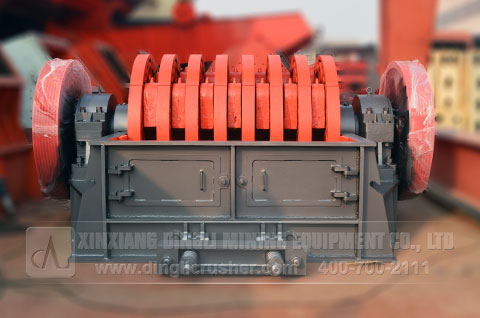

Impact single-stage hammer crusher also called heavy hammer crusher is optimized upon impact crusher and hammer crusher that can crush medium hardness material of limestone with single stage crushing. With low costs, this machine is popular among customers, while many people would doubt about its quality. Thus we will introduce you this condition below.

1. Shell

Crusher shell is the main parts of machine and the protection of all operation parts. Impact single-stage hammer crusher shell has the structure of splice with Q235 steel welding. There are many kinds of welding ways and rules and the most important one is welding material should match the original material. During welding there are many checks to control machine have a high quality of high seal and wear resistant condition. In installation, we use boring and milling machine to ensure its installing precise and using high strength steel to protect its shell.

2. Rotor

Rotor as the core parts of impact single stage hammer crusher, its quality determines the whole machine quality and service life. Rotor mainly consists of main spindle, hammer disc, hammerhead, hammer spindle, and bearing base, which main spindle is made by quality alloy steel, bearing base is made by boring and milling machine, hammer disc and hole is made by heating handle to improve its wear condition , hammerhead is made by component steel material with high hardness and wear resistance condition. Connected hammer head and rotor with hammer spindle and protecting with high manganese steel ring, it can prevent rotor from high speed impact.

3. Auxiliary machine

Impact single stage hammer crusher has elaborate design in shell and rotor and other auxiliary parts. Impact single stage hammer crusher uses high manganese steel liner and adjustable liner to replace traditional grid discharging gate to ensure it has a smooth and endurable discharging and using. Also it has the function of automatic avoiding bulk material and throwing them out of machine with spring device.

Customers

More

- Impact Crusher Spare Parts Changing

- Methods to Extend Service Life of Hammer Impact Crusher

- Reasons & Solution in Abnormal Hammer Crusher Vibrating

- PF Impact Crusher Advantages in Stone Production Line

- Models and Features of Counterattack Crusher

- How to Lower Down Bearing Failure Rates of VSI Crusher

- Reversible Impact Hammer Crusher for Green Stone Plant

- Working Principle & Performance of Dual-Stage Crusher

- Wear Resistant Condition of Impact Single Stage Crusher

- Performance Feature Analysis of Hammer Impacting Crusher