Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderImpeller sand washing machine is used for cleaning & selecting fine-grained and coarse-grained material, especially appropriate for the building sand.

Capacity: 30-600 tons

Treatment: powder and impurities

The final finished sand with high cleanness is achieved after the crushed sand is processed by the sand washing machine, a kind of professional equipment for screening and cleaning the aggregates. The sand washing equipment can be divided into various types based on its operation principle. Among them, the impeller sand washer is more widely used in the sand production line. In the final stage of sand production line, it is used for filtering, screening, dehydration of the finished sand.

Hourly washing sand capacity: 30-600 tons

Impurities for treatment: stone powder and other impurities

Application: factory, construction site, hydropower station, sand production line and so on.

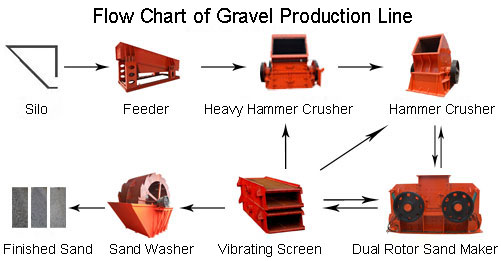

Various types of rock are crushed into coarse sand with the particle size of about 5mm through the crusher treatment; and through the crushing of sand making machine, the coarse sand is processed into the finished sand with the particle size less than 4.75, which is the national standard. Then the finished sand with uniform particle size are screened through the process of vibrating screen. The last step is to obtain relatively clean finished sand after all kinds of impurities are removed through cleaning of sand washing machine.

Spiral sand washing machine (also known as grading machine) in accordance with the different structures, can be divided into single spiral sand washing machine and double spiral sand washing machine,which are mainly used for cleaning, classification and impurities removal of fine and coarse-grained aggregates. Through classification, the aggregates can be graded according to their particle sizes. The sand gravel is agitated mainly through the spiral device so that the soil and water can be mixed. With the sand gravel being gradually screened below the spiral device, the impurities also run out through the water.

From the external structure of view, the impeller bucket wheel sand washing machine completes the cleaning and dehydration of finished sand gravel with the rotation of impeller. The final finished sand with high cleanness is obtained after the impurities removal and dehydration of finished sand. Due to its simple structure and easy operation, such equipment, as a new type upgraded and optimized on the basis of sand making machine, is widely used in various sand washing production lines.

With natural sand resources becoming less and less, the production of artificial sand is very necessary. However, since the environment where the sand gravel exist is linked with the natural world, it is inevitable that the natural sand will be mixed with a lot of sediment in the mining and processing, it is very necessary to clean and screen the sand.

On the other hand, some projects that require the supply of finished sand have relatively high requirements of finished sand for its construction. In some wet sand production line, since the water is needed to produce the finished sand, the final products inevitably have some water. Only through the process of dehydration, the production of final finished sand will be complete.

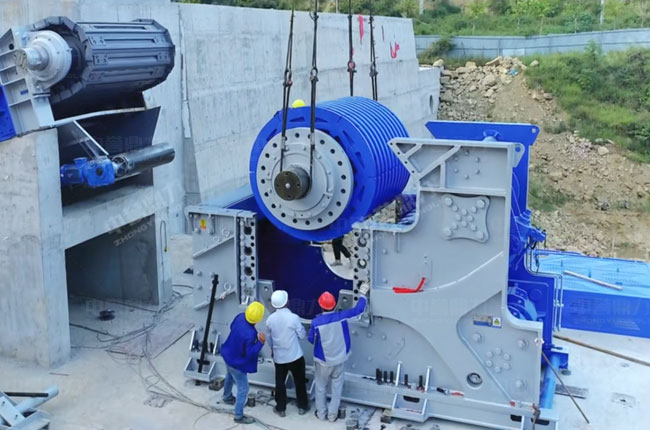

Sand washing production line includes two major processes: the first part is crushing and the second part is the follow-up screening, cleaning, and dehydration process. First of all, the rocks with different harnesses are be crushed through the crusher (generally primary crushing equipment) capable of crushing the aggregates with different strengths; then after a second crushing, the finished products with more granular size are achieved for being processed by the sand making equipment with shaping function; finally the finished sand with various particle sizes are screened by the vibrating screen. Since the finished sand is generally mixed with the soil in mining process, the sand washing equipment shall be equipped for cleaning and screening the soil and impurities in the finished sand. After the completion of dehydration process, the quality finished sand with high cleanness is screened out while the sand with poor grain shape is discarded.

First of all, in the sand washing machine configuration, the sand washing machine shall be selected according to the type of material that requires cleaning, for example, the spiral sand washing equipment is the priority specially for beneficiation process and the bucket wheel sand washing machine is the best choice for wet sand production line configuration.

Only with sealing configuration, can the production environment of sand washing machine be clean; meanwhile, it can also reduce the loss of sand gravel. The fine sand recycling machine shall be equipped if necessary for recycling the useful fine sand in the production line so as to improve the profit of the overall sand production line.

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.