Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderStone crushers refer to the machinery equipment for crushing the bulk stone, limestone, bluestone and other materials.

Capacity: 50 -1000 t/h

Feed size: ≤ 1200mm

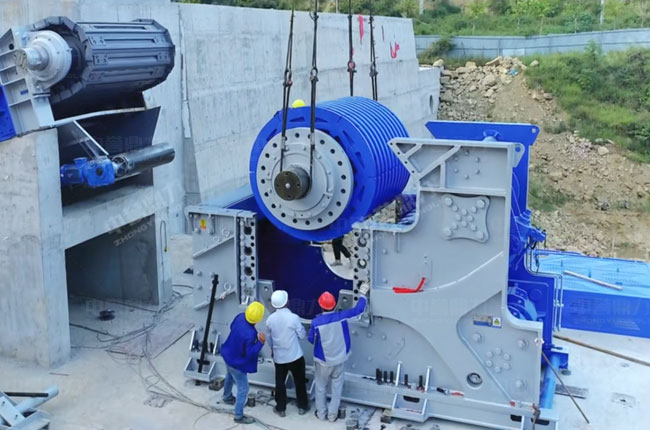

There is a variety of crusher equipment, respectively applied in different production projects, impact crusher for the production of finished gravel project, hammer crusher for stone & fine sand production, ZSJ dual rotor sand making machine for the production project required for sand shaping. With years of experience in the manufacturing and processing of stone crushers, Xinxiang Dingli produced all the types of above-mentioned equipment.

General stone crusher equipment crushes the aggregates through a variety of extrusion, fracture and impact crushing by various parts in the crushing cavity, while the stone crushers manufactured by Dingli crush the aggregates in the crushing cavity through impacting and hammering. Thus you should produce finished gravel materials with the grain shape in line with customer requirements.

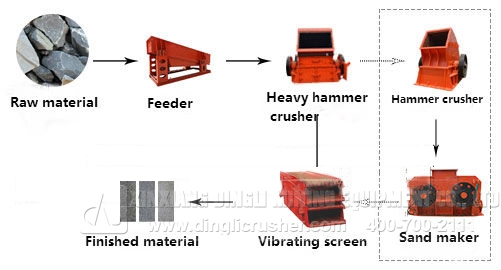

The production line configuration of the stone crusher mainly includes the vibrating feeder, the vibrating screen and the crusher. Different equipment shall be equipped to meet the needs of various production lines. Generally a set of crusher can complete the crushing process of a production line, if necessary, secondary crusher or the sand shaping equipment is needed to meet production requirement.

General production process of the stone crusher includes exploitation of large stone in the mountain, conveying the aggregates less than 1.2m into the crusher by vibrating feeder for crushing and finally conveying the finished stone materials with various particle sizes into different silos through the vibrating screen.

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.