Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderIt is used to crush the limestone, bluestone and other materials with medium hardness less than 200MPa into stone or gravel with required size.

Capacity: 20-3000t/h

Feed size: ≤1200mm

Xinxiang Dingli has more than decade of experience in the manufacturing and processing of stone crushers, which produces various finished materials with sand and gravel as the main types. According to the production process, they can be divided into primary crusher, medium crusher and fine crusher. With different operation principles including extrusion, impact and hammering, the crushers can be divided into jaw crusher, impact crusher, hammer crusher, cone crusher, etc. which are widely used in large stone factory, cement plant and concrete mixing station.

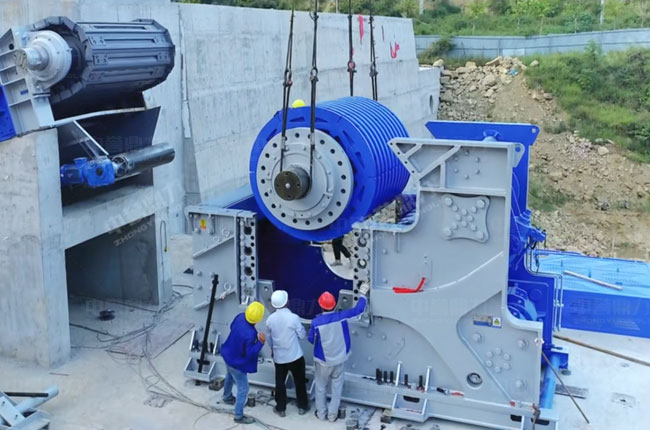

The stone machine manufactured by Dingli mainly is hammer crusher. With electric motor driving the rotors to rotate in high speed within the crushing cavity, the aggregates are crushed into the stone shape. The particle size of finished stone materials can be adjusted by the adjustable lining plate. The finished materials in line with the requirements can be screened out through the sieve.

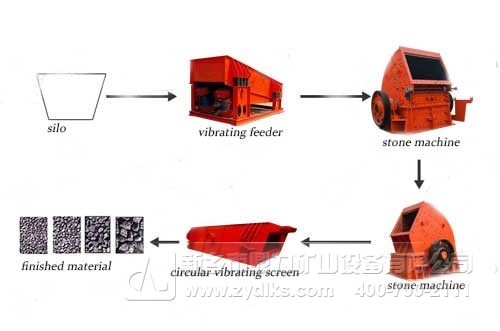

The basic equipment for stone machine production line generally includes vibrating feeder, crusher and vibrating screen. The equipment with different capacity and the sand washer (if necessary) shall be configured to meet the corresponding output requirements of the production line. In the large stone production line, the secondary and tertiary crusher is also needed in case the stone materials with unqualified size can be returned to the crusher for one more time crushing.

Through uniform feeding by our vibrating feeder and primary crushing by the large heavy hammer crusher, the chunks of limestone in the hopper can be processed to the coarse aggregates with a relatively large particle size. These coarse aggregates can be crushed into the fine aggregates by the small secondary crusher through the transmission of conveyor. The finished materials with different particle sizes are finally conveyed to different silos through vibrating sieve of the screens.

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.