Maintenance Tips for Quarry Vibrating Screen

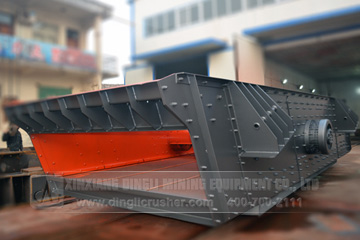

As inevitable equipment in quarry stone crushing line, vibrating screen is mainly applied to dust removal, dehydration, screening and classification of materials. Its stable operation plays a key role in improving efficiency of entire production line. So it is necessary to carry out regular maintenance and repair after purchase of reliable vibrating screen.

The screen frame is mainly composed of side plate, channel steel, tube beam and reinforced plate. It is thus featured by strong inflexibility, simple structure and long service life. Except the screen mesh, there are no other wear parts. The damaged or cracked sieve will directly cause chaos of classification and worsening of quality. Therefore, it is very important to carefully check the mesh after each shut-down of machine. Repair or replace the damaged sieve and clean it with suitable abluent according to the quality of material. For example, the slurry can be cleaned with water. Besides, it is prohibited to contact the mesh with sharp or hard object.

Apart from the sieve, the damping spring should also be checked regularly for fear of its damage or abrasion. Check whether the machine body is damaged out of long-term vibration. Make sure to fasten the anchor bolts with wrench for more than twice within a month. Moreover, periodically check the motor, heart of the vibrating screen and clean the dust on it. Check the wire and connection device for at least one quarter.

It is also important to regularly add lubricating oil for equipment. The motor should be supplied with lithium grease at least every two weeks. Check the bearing after 1500 hours of operation. Make sure the vibration exciter and labyrinth tank are full of lubricating grease. The grease should be added more frequently under the working condition with much dust so as to reduce friction and resistance.

More

- Selection of Circular Vibrating Grading Mesh

- Hosting and Installation Precautions of Vibrating Screen

- Factors to Affect Efficiency of Vibrating Screen

- Cause and Solution of Huge Screen Vibrating

- Exciter to Circular Vibrating Screen Performance

- Solutions for Material Clogging of Vibrating Screen

- Vibrator Screen Diagram

NextContent:none