Vibrating Feeder Instruction

Motor vibrating feeder can be got from the name of working by motor. Vibrating feeder plays an important role in ensuring stable and reasonable production.

With full understanding of vibrating feeder and its operation rule, workers will have a better using. Then Dingli helps us analysis a whole set of using instruction.

Vibrating feeder

Feeding size: ≤1200mm

Production capacity: 40-800tph

Application field: gravel plant, concrete sand making, sand making, and so on.

Material: cobble, granite, basalt, iron, limestone, quartz, coal gangue, and building waste.

Description:

Vibrating feeder is mainly used for continuous and average feeding and screening fine materials for high crushing efficiency. In practical operation, vibrating feeder smoothly feeds material into crusher and has a primary screen. It can be used in coal gangue, beneficiation, building material, and metallurgy.

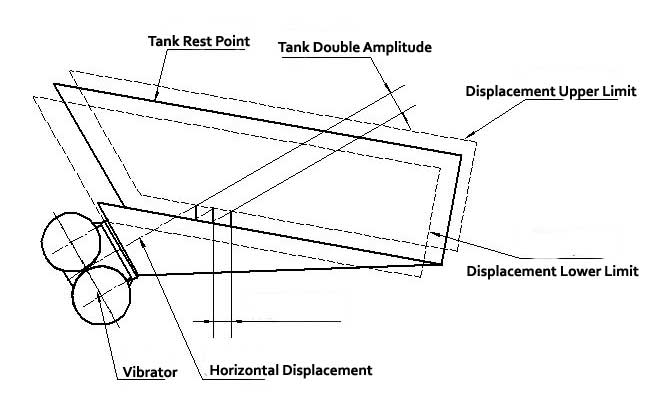

The structure is tank, exciter, spring base, motivation device, and so on. Respectively, exciter is the source of vibration with two eccentric spindles and a gear. In operation, motor drives spindle with v-belt and then the two spindles rotate with an opposite direction for continuously material feeding.

In gravel aggregates production line, feeder can effectively ensure crushing machine have a continuously crush without clogging. The rotating eccentric block of vibrating device can make screen box and vibrating device have a circular movement. And then material will be threw with screen and fed into crusher.

Type

In structure and application field, vibrating feeder can be divided into GZD, ZSW, and GZZ vibrating feeder.

Working principle

Vibrating feeder mainly consists of body, spring, bracket, exciter, motor, and sieve. The exciting eccentric block will have a high-speed rotating motivated by motor through v-belt. With huge centrifugal force, screen box will have a circular movement with vibrating frequency, and then materials will be threw and graded through sieve.

Installation and commissioning

1. Smooth and average feeding, 10 degree descending installation or 15 degree descending installation with adhesion and moisture material.

2. 20mm gap for machine moving and soft and flexible connection.

3. Fasten bolts once 3-5h.

4. Counter motor rotation, stable and low noise and current.

5. Add grease once two months and add lubrication oil monthly.

Performance feature

1. Stable vibration, reliable operation, and long service life.

2. Adjustable exciting force, controllable traffic, and convenient adjustment.

3. Low noise and energy consumption, and less material clogging.

4. Simple structure, reliable operation, easy adjustment and installation, light weight, small volume, easy maintenance, and enclosed structure.

Operation technology

Maintenance

1. Gear oil with geological and temperature demand.

2. Oil should be more than oil standard level, add oil once 3-6 months and clean its box and gear.

Safe technology

1. Safe operation technology education to workers

2. Forbid standing beside machine in operation, forbid adjusting, cleaning, or maintaining machines in operation.

3. Regular check wire wear and electric leakage.

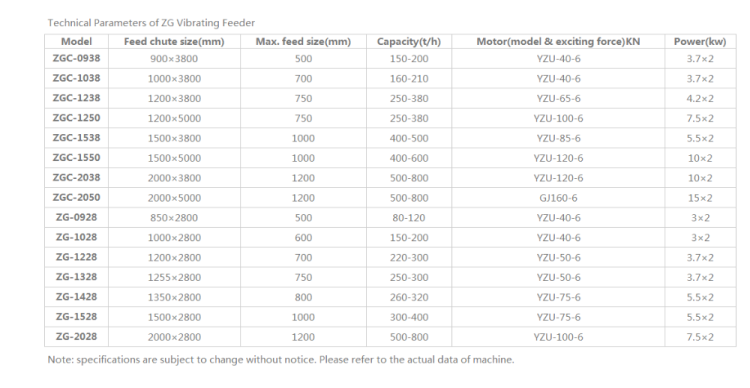

Technicial Parameter

Company recommendation

Dingli, with several years’ experience in manufacturing vibrating feeder, hammer crusher, dual rotor sand maker, vibrating screen, and so on, can ensure its machine quality and performance feature. Dingli, with a great amount of praise and customers around the world, will don’t let you down.

E-mail: dingli@dinglicrusher.com

Tel: 400-700-2111

Customers

More

- Technical Parameters as Reference for Vibrating Feeder Produ

- Elements of Vibrating Feeder Quotation

- Vibrating Feeder Design and Quotation

- Installation Requirements for Vibrating Feeder

- Technical Parameters as Reference for Vibrating Feeder Produ

- Feeder Structure Diagram

- Elements of Vibrating Feeder Quotation

- Common Factors to Block Vibrating Feeder

- Failure Causes and Selection Standard of Motor

- Vibrating Feeder Instruction