Vibrating Feeder Installation and Maintenance Tips

Vibrating feeder also called vibrating feeding machine can convey bulk and particle materials into receiving machine smoothly. Vibrating feeder as an essential machine in gravel aggregates production line can also screen material. It is widely used in mining, coal, beneficiation, building material, and chemical industry.

In operation, vibrating feeder needs many safe operation rule and installation and maintenance tips.

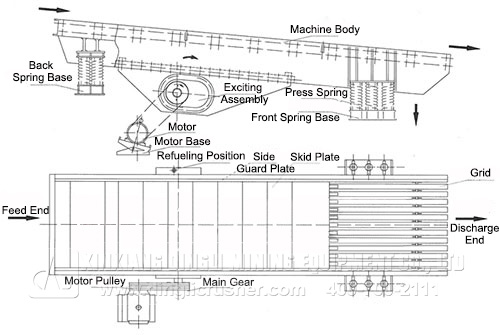

Vibrating feeder installation requirements

1. Vibrating feeder has average and stable material feeding. And you should install machine with some angles of 10 degree or 15 degree with abrasive materials.

2. Vibrating feeder should have 20mm space and flexible connection.

3. Fasten bolts before opening feeder and regular fasten them 3-5 hour per times.

4. Ensure have opposite rotating of vibrating motors.

5. Lubricate machines two months per times and check machines as there is abnormal noise.

Maintenance tips:

1. Check machine vibration frequency, motor current and motor temperature.

2. Lubricate motor bearing parts (two months per times), change inner bearing parts (six months per times).

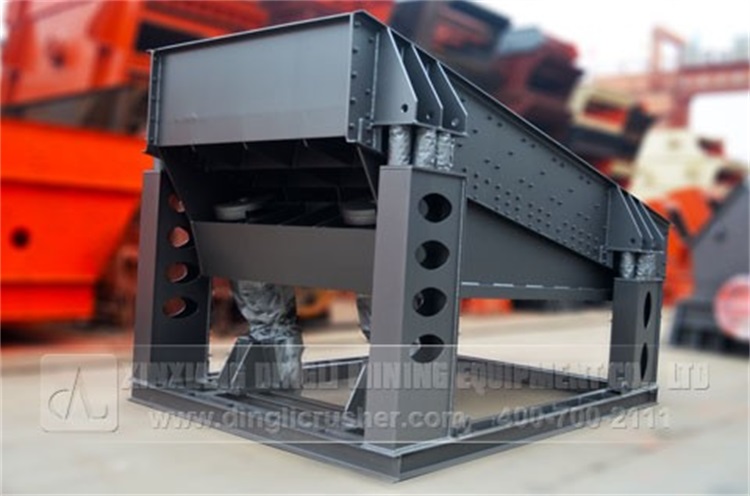

Zhongyu Dingli produces huge vibration feeder. Dingli is responsible to place inspection, machine selection, installation and commissioning, and launching and acceptance. More vibratory feeder price and other information can be got from online service or e-mail of dingli@dinglicrusher.com.

Customers

More

- Vibrating Feeder Installation and Maintenance Tips

- How to Choose Vibrating Feeder?

- Using Process & Attention of Feeder in Gravel Production

- Vibrating Feeder Role in Gravel Aggregates Production Line

- Failure Causes and Selection Standard of Motor

- Using Process & Attention of Feeder in Gravel Production

- Elements of Vibrating Feeder Quotation

- Using Process & Attention of Feeder in Gravel Production

- Elements of Vibrating Feeder Quotation

- Common Factors to Block Vibrating Feeder