Installing and Commissioning Tips Vibratory Feeder Hopper

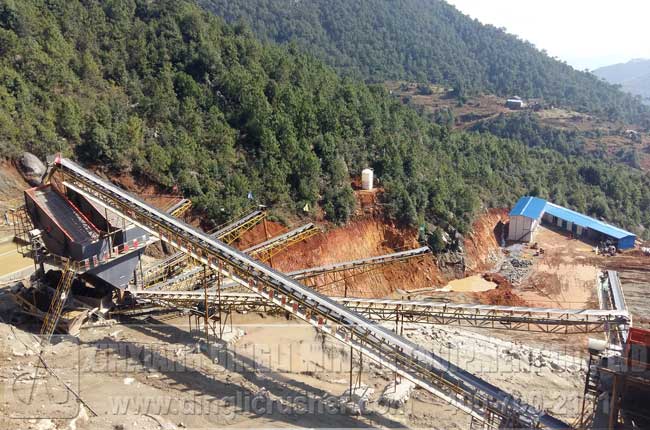

In stone production, it is important to ensure stable operation in stone production line. In mining industry, vibrating feeder hopper is a new feeding machine installed below hopper. This can effectively solve the problems of clogging, adhesion, and bridging.

Many vibrating feeders are designed by moving with gravity. In dismantling material, this technology is easy to reach. While in actual production, there will have moisture and adhesive materials restraining material moving.

Attention in installing and commissioning vibrating feeder

1. Check pre-dig foundation of machine with installation diagram.

2. Have 50-80mm gap with installation place.

3. Install motor in no more than 1/4 height of hopper.

4. Fasten motor bolts.

5. Check the installation condition of drive device.

6. Ensure workers in a safe place before opening machine.

7. Have no more than 4h testing operation.

Common problem and solution

1. Abnormal noise

Check and fasten bolts, adjust hopper with not less than 50mm gap, if there are cracking noise in hopper with other machines.

2. Low production capacity

Small exciter force, large material moisture and adhesion will influence material flow speed. Adjusting eccentric angle improves motor exciter force and reducing ball plate size increases material flow scale.

3. Fasten flange and hopper for sealing material feeding

Change sealing ring and canvas.

Here are the tips you should pay attention in machine installation and commissioning. If you have any question about vibrating feeder, please contact us with www.dinglicrusher.com, dingli@dinglicrusher.com, 400-700-2111.

Customers

More

- Vibratory Feeder Design, Price, and Usage Introduction

- Vibrating Feeder Role in Gravel Aggregates Production Line

- Feeder Structure Diagram

- Feeder Structure Diagram

- Feeding Machine Advantages of Under Bin Feed

- Failure Causes and Selection Standard of Motor

- Elements of Vibrating Feeder Quotation

- Vibrating Feeder Installation and Maintenance Tips

- How to Choose Vibrating Feeder?

- Feeder Structure Diagram