Gravel Feeding Machine Type and Working Principle

Feeding machine has the type of heavy, medium, and light. It is widely used in mining, beneficiation, chemical, building material, and cement industry for material conveying and crushing. There are inclined and level installation methods. Compared with crusher machine, it has smaller function but it weighs much on material conveying.

Gravel material feeding working principle:

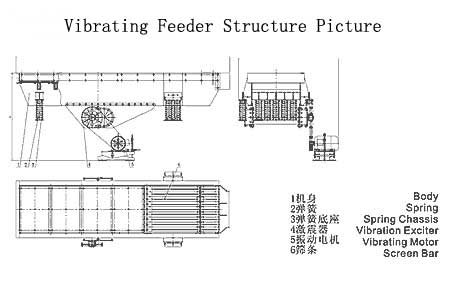

Vibrating feeder consists of tank, exciter, spring base, and rotary device. Motivated by exciter, motor can move spindle with belt, and then spindle will make gear move and then vibrating tank for material conveying.

Gravel feeder performance feature:

1. Small volume, light weight, and simple structure.

2. Easy installation and maintenance, low operation cost.

3. High efficiency, large feeding ability, fastened spare parts, and less lubrication.

4. Resonance working principle, lower noise, less energy consumption, and higher power rates.

5. Stable vibration, average feeding, and longer service life.

Gravel feeder technology parameter:

| Type |

Feed Chute (mm) |

Material Size(mm) |

Production Capcity (t/h) |

Motor KN |

Power (kw) |

| ZGC-0938 | 900×3800 | 500 | 150-200 | YZU-40-6 | 3.7×2 |

| ZGC-1038 | 1000×3800 | 700 | 160-210 | YZU-40-6 | 3.7×2 |

| ZGC-1238 | 1200×3800 | 750 | 250-380 | YZU-65-6 | 4.2×2 |

| ZGC-1250 | 1200×5000 | 750 | 250-380 | YZU-100-6 | 7.5×2 |

| ZGC-1538 | 1500×3800 | 1000 | 400-500 | YZU-85-6 | 5.5×2 |

| ZGC-1550 | 1500×5000 | 1000 | 400-600 | YZU-120-6 | 10×2 |

| ZGC-2038 | 2000×3800 | 1200 | 500-800 | YZU-120-6 | 10×2 |

| ZGC-2050 | 2000×5000 | 1200 | 500-800 | GJ160-6 | 15×2 |

| ZG-0928 | 850×2800 | 500 | 80-120 | YZU-40-6 | 3×2 |

| ZG-1028 | 1000×2800 | 600 | 150-200 | YZU-40-6 | 3×2 |

| ZG-1228 | 1200×2800 | 700 | 220-300 | YZU-50-6 | 3.7×2 |

| ZG-1328 | 1255×2800 | 750 | 250-300 | YZU-50-6 | 3.7×2 |

| ZG-1428 | 1350×2800 | 800 | 260-320 | YZU-75-6 | 5.5×2 |

| ZG-1528 | 1500×2800 | 1000 | 300-400 | YZU-75-6 | 5.5×2 |

| ZG-2028 | 2000×2800 | 1200 | 500-800 | YZU-100-6 | 7.5×2 |

Vibrating feeder works for screening and feeding materials in gravel aggregates production line. With the demand of crushing and screen technique process, there are different vibrating feeding machine types.

Gravel production line application of feeder:

Attentions in using gravel feeder:

1. Install on the base and then stop machine rotor with wood or brake.

2. Check machine rotating condition and fasten machine belt.

3. Ensure machine opening non material.

4. Orderly start up machine before feeding materials.

5. Make sure motor has better insulation efficiency.

Zhongyu Dingli gravel production line has many years’ experience in mining machine manufacturing, the mining machines they produced are with higher quality and abundant machine type. Also we have professional technicians for machine production line and plan making.

More machine information by contact our online service or e-mail of dingli@dinglicrusher.com.

Customers

More

- Elements of Vibrating Feeder Quotation

- Importance of Electric Feeder in Mining Industry

- Vibrating Feeder Design and Quotation

- Vibrating Feeder Instruction

- Vibrating Feeder Installation and Maintenance Tips

- Importance of Controlling Feeding Quantity in Crushing

- Working Principle & Features of Vibrating Feeder

- Common Factors to Block Vibrating Feeder

- Technical Parameters as Reference for Vibrating Feeder Produ

- Importance of Electric Feeder in Mining Industry