Attentions for Proper Operation of Vibrating Screen

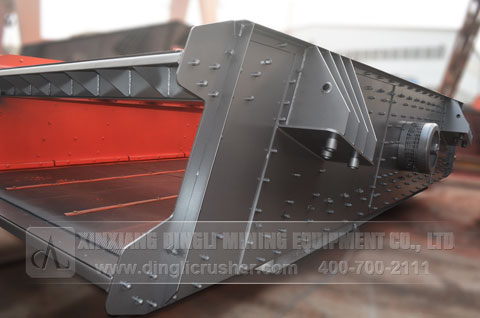

Vibrating screen is applied to screen the materials and remove the impurities in the stone crushing line. In order to reduce the failure and extend service life of the screen, we would like to share the following tips.

Before correct installation of the vibrating screen, check whether the spring is damaged and the angle of vibrating motor is well adjusted. Besides, make sure the bolts and v-belt are tightened, the screen plate is not clogged by the foreign materials and screen surface is flat.

After normal operation, make sure the nozzle of vibrating screen is not clogged and there is no abnormal noise of motor. Remember to regularly check the materials incoming and discharge condition.

Do not shut down the screen until all the materials on the sieve have been processed. Make sure the screen will not collide with other device at the resonant point. Clear away the residual impurities after the screen enters into drop-dead halt.

As long as we pay attention to the mentioned details during operation, the vibratory screen equipment can be stably operated with long service life.

More

- 8 Tips to Improve Efficiency and Effect of Vibrating Screen

- Mining Vibrating Screen Type Parameter and Company

- Vibrating Screen Maintenance and Reasons of Clogging

- How to Select Suitable Vibration Screen among Mining Market?

- Four Tips for Improving Efficiency of Vibrating Screen

- Analysis on Stone Plant Vibrating Screen Maker Spare Parts

- Vibrating Feeder Application Field and Working Principle

NextContent:None