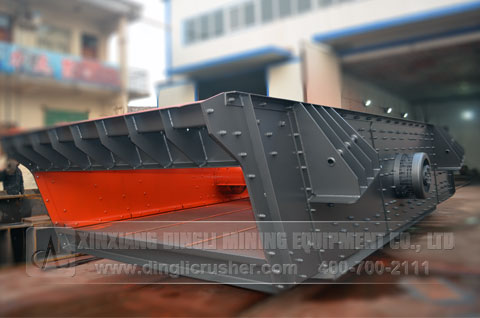

Main Wear Parts and Maintenance of Vibration Screen

As main equipment for screening and transporting materials, the vibrating screen will inevitably suffer certain abrasion after long-term operation. So it is necessary to carry out regular maintenance for its spare parts so as to improve service life of the equipment.

The sieve plate should have sufficient strength, large open area and little clogging. The sieve plates are generally formed by bar, punching or seam, etc. In order to achieve the best effect, it shall select proper sieve plate based on specific application of equipment.

Rubber spring can buffer some impact suffered by screening equipment. The spring may be damaged in the operation, so it should be stocked in case of need. Compound rubber spring is a better choice for the screen equipment which shall process large quantity of material.

As driving source of vibration screen, the exciters are symmetrically distributed on the two sides of screen box. The four groups of eccentric blocks are connected by couplings, which may be broken out of constant rotating. So it is advised to store some extra parts.

More

- 8 Tips to Improve Efficiency and Effect of Vibrating Screen

- Mining Vibrating Screen Type Parameter and Company

- Vibrating Screen Maintenance and Reasons of Clogging

- How to Select Suitable Vibration Screen among Mining Market?

- Four Tips for Improving Efficiency of Vibrating Screen

- Analysis on Stone Plant Vibrating Screen Maker Spare Parts

- Vibrating Feeder Application Field and Working Principle

NextContent:None