Stone Crushing Production Line

In the stone crushing line, the discharged material with particle size larger than 3mm accounts for 50% of the total discharge. Based on the feeding and discharging size, the crusher can be divided into primary, secondary and fine crusher. It is suitable for crushing limestone, granite, basalt, river pebble and metallurgical slag with wide application in water & electricity, building material, highway and urban construction.

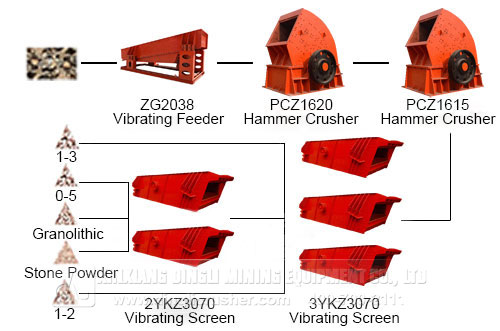

The general configuration for stone crushing line with the hourly capacity of 50-500 ton includes vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centralized electricity control. In order to meet various requirements of customers, we may configure cone crusher and dedusting equipment, etc.

| Equipment | Model | Power(KW) | Set(s) | Market Price |

| Vibrating Feeder | ZG2038 vibrating feeder | 3.7*2 | 1 | Inquiry |

| Crusher | PCZ1620 heavy hammer crusher | 400*2 | 1 | Inquiry |

| PCZ1615 heavy hammer crusher | 200*2 | 1 | Inquiry | |

| Vibrating Screen | 3YK3070 vibrating screen | 45 | 1 | Inquiry |

| 2YK3070 vibrating screen | 37 | 1 | Inquiry |

- Highly automatic.

- Adjustable discharge size and efficient crushing.

- Energy-saving, low cost, large capacity and high profit.

- Uniform finished stone size and sound shape with national requirement.

- Energy-saving, low cost, large capacity and high profit. Please feel free in contacting us for details.

More

- Stone Crushing Line Equipment | Stone Crusher Plant Layout a

- Attentions of Problems in Building Crushing Plant

- Rock Crushing Line Layout and Operation Process

- Attention in Joint Design of Crusher and Screener

- Quotation of Mica Stone Crushing Production Line with 300,00

- Configuration of Road Stone Crushing Plant Machines

- 1500Ton Production Line Costs, Crusher Price

NextContent:none