Full Explanation of Crusher

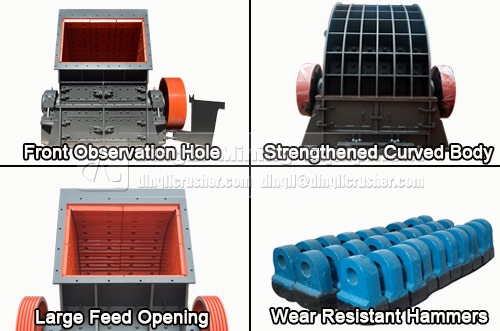

As a professional hammer crusher manufacturer, Xinxiang Dingli has the production ability of all sorts of crusher machine. Then we will introduce you the most important machine of heavy hammer crusher.

Core working principle: hammerhead hits materials motivated by high-speed motor. And then crushed material is discharged from crusher through liner and hammerhead. In crushing, there is wet, semi-wet, and dry crushing system. Dry crushing system refers to separating material with air maneuver sorting system, which should install a dust collector. Wet crushing system will add water as crushing material. And semi-wet crushing system refers to adding less water for clean production in crushing material.

Main spare parts: hammerhead and rotor are the main parts in hammer crusher. In making hammerhead, there are two ways of forging and casting. Forging has the better effort than casting with less transporting problems and ability in crushing high hardness material. So, forging hammer crusher has higher price than casting crusher and you can choose machine with your production demand.

Main texture: high chrome alloyed hammerhead has high wear-resistant and fine performance feature. This character not only gains many customers’ praise and helps many customers find a new ground in wear-resistant parts. Excellent cost effectiveness will bring sound economic interests for customer. Practice shows that high chrome alloyed hammerhead has four times service life and twice price than high manganese hammerhead. So, this kind of hammerhead is the best choice for mining industry of medium and small gravel industry and brick plant.

Application field: with high chrome hammerhead, Dingli hammer crusher has a larger application field of limestone, gravel, coal gangue, and so on. Hammerhead is with the most advanced compound technology with low broken and wear condition. Also this hammerhead solves the problems of hardness and tenacity and can be used in complex and poor working condition.

NextContent:none