Introduction of Single Cylinder Hydraulic Cone Crusher

Single cylinder hydraulic cone crusher features with advanced structure design, excellent crushing ability, fine reliability, and low production cost. This kind of machine is moved by single cylinder for mining gate adjustment, cleaning, and loading protection. Also by installing smart intelligent controlling system of mining gate, there is more production control and operation optimization. So, it has a wide range of application in dark, color, nonmetal, and gravel industries.

Working principle

In operation process, small gear will be motivated by motor and then it will also drive large gear, eccentric parts, and main spindle parts for revolution in copper liner and rotation of spindle.

Non-loading operation will have a revolution of main spindle and large gear. The operation trail of inner cone will swing in the crusher chamber and materials will be crushed by cone. The connection parts of supporting and bracket is squeezed by hydraulic cylinder. The movable cone is lifted by hydraulic piston for adjusting discharging gate and preventing mineral clogging.

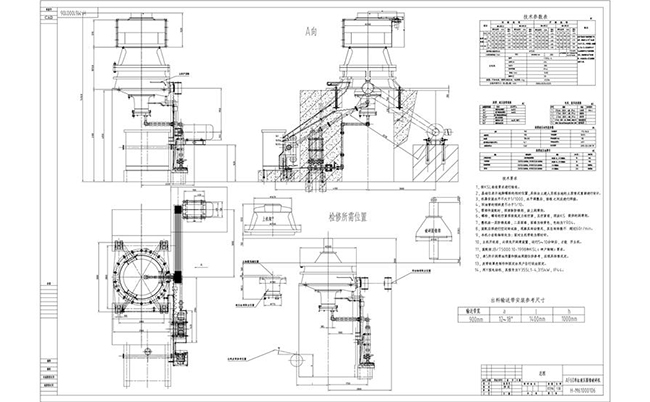

Structure component

1. Upper bracket assembly: upper bracket, rolling mortar wall, pad hat, protection liner.

2. Lower bracket assembly: lower bracket, protection plate, inner liner, and eccentric bush.

3. Mobile cone assembly: spindle, body, and crushing wall.

4. Driving shaft assembly: tank wheel, driving shaft, bearing, bracket, and small gear.

5. Eccentric sleeve assembly: ring, eccentric sleeve, bigger gear, and spindle sleeve.

6. Hydraulic cylinder assembly: middle fraction tray, lower fraction tray, hydraulic cylinder, cylinder sleeve, cylinder bottom, displacement sensor.

Core technology

1. Hydraulic system

Single cylinder hydraulic cone crusher has the ability of hydraulic adjustment and protection.

Adjustment: in normal operation, hydraulic pump will input or discharging oil through spindle cylinder. This also make spindle have a upper or lower moving and gap between rolling mortar wall and crushing wall narrow and enlarge for adjusting discharging gate.

Cleaning: when there is foreign material or overloading of machine, hydraulic protection system will take its effect in protection. And main spindle will have down working and then enlarging discharging gate for foreign material output. When there is foreign material in the gate, cleaning system should be used for discharging foreign materials with larger mining gate.

2. Lubrication system

Dual oil input with main spindle and driving shaft. In main spindle, lubrication oil will lubricates bearing parts, ball tile, sleeve, spindle sleeve, and gears. In other parts, oil will lubricates sleeve and then discharged from the gate.

Performance feature

1. High efficiency: with dual supporting, it can hold larger crushing force.

2. Larger production capacity: perfect match of travel, crushing speed, and crushing chamber make it have higher production capacity of 35%-60% than traditional one.

3. High quality stone: with unique crushing chamber and crushing principle, it can produce material with average shape and less plate.

4. Wide application for multi-chamber.

5. Loading protection and fine lubrication for dual insurance.

6. Easy maintenance: simple and compact structure, stable performance, and high quality.

Application

It is widely used in metallurgy, building, road, chemical, and relevant industries for crushing medium hardness material. It has the feature of large crushing ratio, higher efficiency, low energy consumption, and average material size.

All the words above are the introduction of single cylinder hydraulic cone crusher. Inquire the machine detail with dingli@dinglicrusher.com, www.dinglicrusher.com/contact/, or 400-700-2111.

NextContent:none