Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | CSB160 | ||

| Closed Side (mm) | 109 | 188 | 216 |

| Open Side (mm) | 137 | 210 | 241 |

| Adjustable Discharge Opening Size (mm) | 13 - 31 | 16 - 38 | 19 - 51 |

| Power (kW) | 185 | ||

| Output (tons/hour) | 109 - 181 | 132 - 253 | 172 - 349 |

*Note: The processing capacity of the CSB160 cone crusher may vary with different materials and feeding sizes.

The 1200tph large stone production line configured by us for Wuxue Hubei mainly adopts PCZ1820 heavy hammer crusher PCX1220 shaping hammer crusher several sets of efficient vibrating screens and auxiliary dedusting facilities.

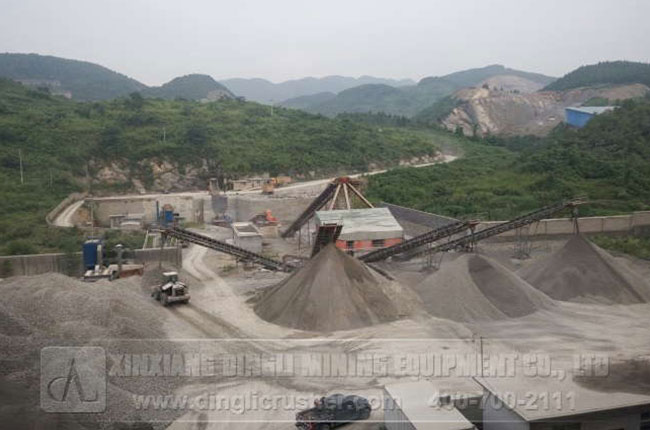

This a complete crushing and screening plant for construction aggregate production including crushed stone and artificial sand. The output is 350 ton per hour and raw material is limestone. Please see the pics for its layout and equipment configured

As we can see from the production site the arrayed equipment successively produced numerous finished gravels and then was sent into the cement production projects which has lower production costs.

Before starting the CSB160 crusher, a thorough inspection is essential. Check the feed opening and discharge port for any obstructions or residual materials. Examine the power connections and ensure the power rating is within the 6 - 185kW range as per the crusher's requirements. Inspect the springs for any signs of damage or wear, as they play a crucial role in the crusher's operation and safety. Also, verify the integrity of the mantle and concave bowl to ensure proper crushing action.

When operating the CSB160, start by setting the desired discharge port size according to the required output particle size. For example, if a finer output in the range of 6 - 19mm is needed, adjust the settings accordingly. Gradually increase the power input, starting from the lower end of the 6 - 185kW range and adjusting based on the material being crushed. Monitor the crusher's production rate, which can vary from 109 - 181 tons/hour, 132 - 253 tons/hour, or 172 - 349 tons/hour depending on the feed and discharge port configurations. Ensure a steady flow of material into the crusher, avoiding overloading or underfeeding.

Regular maintenance is key to the longevity of the CSB160. Daily, check for any loose bolts or fittings and tighten them if necessary. Weekly, clean the exterior of the crusher to prevent the buildup of dust and debris. Monthly, inspect the wear parts such as the mantle and concave bowl. If the wear exceeds a certain limit, plan for replacement. Every three months, check the condition of the springs and replace them if they have lost their elasticity or are damaged. Also, during these intervals, inspect the lubrication system and refill or change the lubricant as needed to ensure smooth operation of the moving parts.

If the crusher experiences a sudden decrease in production rate, it could be due to a clogged feed or discharge port. Stop the crusher and clear the obstruction. If there is excessive vibration, check the balance of the rotating parts and the alignment of the mantle and concave bowl. Unusual noises may indicate a problem with the bearings or a foreign object in the crushing chamber. Inspect and repair or remove the object as appropriate. If the crusher fails to start, check the power supply, fuses, and control panel for any faults.

We are present worldwide and always here to help.

Get in touch today!