Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | PSGD0603 |

| Max feed size | 30 mm |

| CSS Range | 3 - 13 mm |

| Capacity(by hour) | 9 - 35 t/h |

| Motor power | 30 kW |

| Dimensions | 2195×1158×1651 |

| Weight | 4500 kg |

*Note: The processing capacity of the PSGD0603 cone crusher may vary with different materials and feeding sizes.

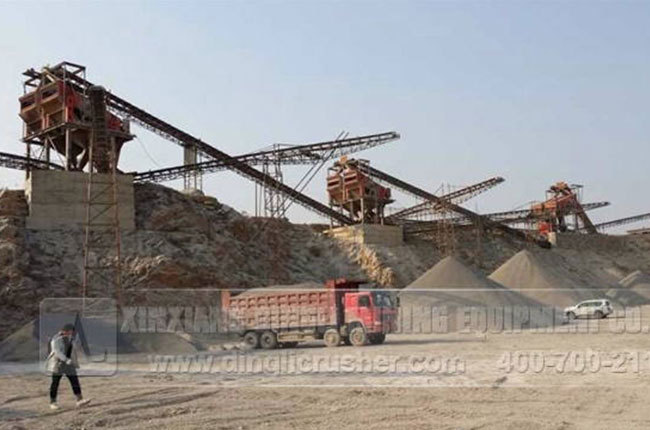

The project is an expansion project, the crushing raw material is limestone, the production capacity is required to be 800-1500 tons, and the finished material is used for construction.

This 1400tph production line is configured with 3 sets of vibrating screen running side by side the efficiency of which is 50% higher than that of combined screening of two screens.

Completed in : 2018-01 Designed by : Xinxiang Dingli Mining Equipment Co. Ltd. Background : Such 3000tph aggregate production line is built through integration of previous six small aggregate production lines. Design feature : The belt conveyor syst

In the domain of industrial crushing, the PSGD - 0603 crusher with the 2'FT specification is an excellent choice for fine - crushing operations. Its unique technical parameters contribute to high - quality and efficient performance.

Specification: 2'FT

Model: PSGD - 0603

Cavity Type: Short - head Fine

Large - end Diameter of Crushing Cone: 600 mm

Discharge Opening Adjustment Range: 3 - 13 mm

Feed Size at the Opening Edge with Recommended Minimum Discharge Opening: 35 mm

Maximum Feed Size: 30 mm

Processing Capacity: 9 - 35 t/h

Power of Main Motor: 30 kw

Machine Weight: 4500 kg

Overall Dimensions: 2195×1158×1651 mm

1. Precise Fine - Crushing: The short - head fine cavity type and the ability to adjust the discharge opening from 3 to 13 mm allow for precise control of the final particle size. This is ideal for applications where fine - grained products are required, such as in the production of high - grade powders or fine aggregates.

2. Accommodating Feed Sizes: With a recommended feed size of 35 mm at the opening edge for the minimum discharge opening and a maximum feed size of 30 mm, the crusher can handle pre - processed materials of appropriate sizes. This ensures a smooth and efficient crushing process, reducing the likelihood of blockages.

3. Optimal Processing Capacity: The processing capacity of 9 - 35 t/h makes it suitable for small - scale to medium - scale fine - crushing projects. It can provide a consistent supply of finely - crushed materials while maintaining energy - efficient operation.

4. Energy - Saving Motor: Powered by a 30 - kw main motor, the crusher strikes a good balance between power consumption and crushing performance. This energy - efficient design helps to cut down on operating costs over time.

5. Compact and Easy - to - Manage: Weighing 4500 kg and having overall dimensions of 2195×1158×1651 mm, the crusher has a compact structure. It is easy to install, operate, and maintain, making it a practical option for sites with limited space or those with specific layout requirements.

We are present worldwide and always here to help.

Get in touch today!