Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | PYFB0918 |

| Max feed size | 150 mm |

| CSS Range | 25 - -38 mm |

| Capacity(by hour) | 118 - 163 t/h |

| Motor power | 75 kW |

| Weight | 12.2 t |

*Note: The processing capacity of the PYFB0918 cone crusher may vary with different materials and feeding sizes.

Nominal capacity181 - 327 t/h

Max. feed size178 mm

Motor power250 kW

Live ChatNominal capacity258 - 417 t/h

Max. feed size205 mm

Motor power250 kW

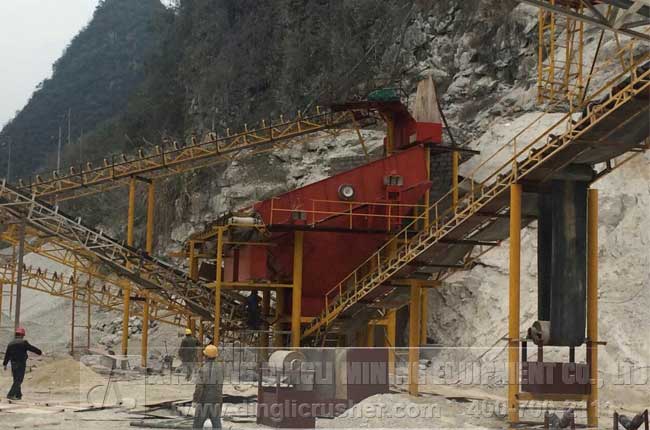

Live ChatAt the production site it is seen that by adopting the crusher with hourly capacity of 1200 ton the production process is greatly simplified compared with previous production lines configured with more than one crusher.

In this aggregates production plant we get to know it builds near mountain for rich local natural resource low transportation energy costs and high productivity.

This production line is especially constructed for the building stone with wide application of finished material and optimized operation efficiency.

Maximum Feed Size: 150mm, capable of directly crushing relatively large - sized materials and reducing the pre - treatment process.

Discharge Opening Adjustment Range: 25 - 38mm, enabling precise control of the discharge particle size according to different production requirements.

Power: 75kW, providing sufficient power for the stable and efficient operation of the crusher.

Production Capacity: 118 - 163t/h, ensuring a stable output under different production scales.

Weight: 12.2 tons. The structure is compact and solid, which is not only convenient for installation and movement but also ensures operational stability.

Advanced Chamber Design: It adopts the STD EC chamber type. The unique chamber structure has been carefully optimized. This makes the movement trajectory of materials in the crushing chamber more reasonable, fully utilizes the crushing force, improves the crushing efficiency and product quality, and produces more uniform finished product particle sizes.

Flexible Discharge Adjustment: The 25 - 38mm discharge opening adjustment range is flexibly designed. Operators can quickly and accurately adjust the discharge opening size according to different production needs, such as producing building sand and gravel, to adapt to diverse production scenarios.

Efficient Power Configuration: The 75kW power configuration is just right. It can meet the power requirements of the equipment when processing materials of various hardnesses and avoid unnecessary energy waste, achieving a balance between efficient production and energy conservation.

Stable Structural Design: The overall weight of the equipment is 12.2 tons. The reasonable weight distribution combined with the strong structural design ensures that the equipment has good stability during operation, reduces vibration and noise, prolongs the service life of the equipment, and reduces maintenance costs.

High Maintenance Convenience: The overall structure design of the equipment takes into account the convenience of maintenance. The key components are easy to disassemble and install. Daily inspection and maintenance work can be completed quickly, reducing downtime and improving production efficiency.

We are present worldwide and always here to help.

Get in touch today!