Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Cavity Type | Cavity | Feed opening (mm) | Maximum feed (mm) | Discharge port (mm) | Motor power (kw) | Main Unit Weight (kg) | Processing capability (t/h) |

| XGP100S | A | 320 | 250 | 35 - 100 | 75 - 90 | 9500 | 140 - 520 |

| B | 250 | 210 |

*Note: The processing capacity of the XGP100S cone crusher may vary with different materials and feeding sizes.

All the equipment has been equipped with dust-proof facility and observation device so as to timely observe the abnormal situation and make adjustment.

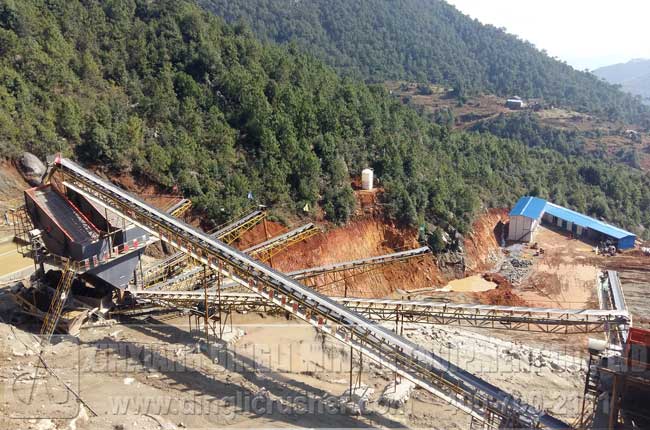

The above pictures show production site of hard rock crusher plant. Unlike traditional crushing plant it adopts only one set of hard rock crusher to complete the crushing process which greatly reduces the equipment investment and increase

In the production site of customer it can be seen that the raw materials of sand making are mainly the stones with large grain size and through being crushed these stones are finally used for sand making.

We are present worldwide and always here to help.

Get in touch today!