Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | 1300 x 1050 |

| Max feed size | 1000 mm |

| Motor power | 200 KW |

| Weight | 38,000 Kg |

*Note: The processing capacity of the 1300 x 1050 jaw crusher may vary with different materials and feeding sizes.

Nominal capacity290 - 845 tph

Max. feed size1250 mm

Motor power160 KW

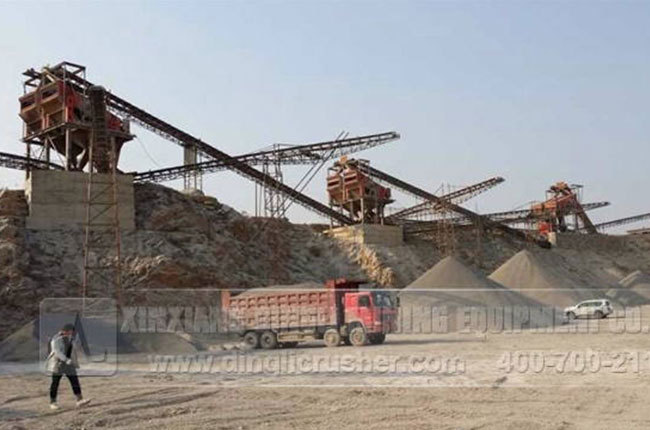

Live ChatThis is an energy-saving and highly efficient stone production line. The equipment configured also as the main mining products for crushing and screening is very suitable to process local limestone.

This 2,000 tons of sand and stone production line project is built in the form of EPC general contract, mainly crushing limestone, the use of hammer crusher as the main crushing equipment, the total investment of the project is $3,508,2303.0830, the annual output value is 6 million tons.

This 1400tph production line is configured with 3 sets of vibrating screen running side by side the efficiency of which is 50% higher than that of combined screening of two screens.

Since their inception, jaw crushers have undergone numerous technological innovations, making them more efficient and reliable. Today, jaw crushers are indispensable in industries such as mining and construction.

Technological advancements have elevated the performance and applications of jaw crushers.

Innovative Design: Advanced single-toggle mechanisms enhance crushing force.

Automated Control: Automation systems improve operational precision.

Advanced Materials: High-performance alloy materials increase the wear resistance of jaw plates.

Energy Efficiency: Optimized energy utilization reduces power consumption.

Modular Manufacturing: Standardized parts facilitate maintenance and replacement.

These innovations have made jaw crushers more competitive in practical applications.

We are present worldwide and always here to help.

Get in touch today!