Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | CJ160 |

| Feed opening | 1600×1200 mm |

| Max feed size | 960 mm |

| CSS Range | 150-300 mm |

| Capacity(by hour) | 300-1260 tph |

| Motor power | 250 KW |

*Note: The processing capacity of the CJ160 jaw crusher may vary with different materials and feeding sizes.

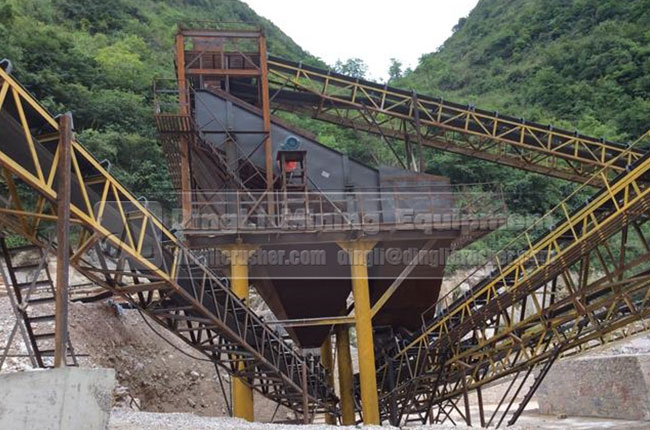

Equipment configuration: PCZ1512 heavy hammer crusher ZGC1238 vibrating screen*2 ZSJ1215 dual rotor sand making machine.

There are hammer crushers placed side by side in the opposite direction. The raw materials and unqualified materials are conveyed into crushers through transmission pipeline for fine material shape. This production line is wholly designed b

Machine: ZGC1538 vibrating feeder + PCZ1615 heavy hammer crusher + 4*YKZ2460 vibrating screen + ZSJ 1218 dual rotor sand maker

Technical Specifications:

Model: CJ160

Max. Feeding Size: 1600×1200 mm

Range of Discharging Port: 150-300 mm

Handling Capacity: 300-1260 tph

Power: 250 KW

The CJ160 jaw crusher is designed with operational stability in mind, ensuring continuous and reliable performance across a range of applications. Its features are tailored to provide a balance between efficiency and durability.

Sturdy Frame: Cylindrical pins and bolted connections in the frame ensure a robust and reliable structure.

Enhanced Crushing: Improved motion parameters lead to efficient crushing throughout the chamber, with a larger stroke and higher crushing ratio at the bottom.

Compact and Reliable: The compact design makes it suitable for both fixed and mobile crushing plants, ensuring stable operation.

Installation Flexibility: Detachable design facilitates easy transportation and installation, making it ideal for underground operations.

Extended Lifespan: The bearing design is optimized for longevity, and standardized components reduce the need for a variety of spare parts.

This model is suitable for crushing materials such as river pebbles, granite, basalt, iron ore, limestone, quartz, diabase, construction waste, iron ore, and gold.

We are present worldwide and always here to help.

Get in touch today!