Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | PEJ0912 |

| Feed opening | 900 x 1200 mm |

| Max feed size | 750 mm |

| CSS Range | 130 ± 35 mm |

| Capacity(by hour) | 180 tph |

| Motor power | 110 kW |

| Rotation speed of eccentric shaft | 380 r/min |

*Note: The processing capacity of the PEJ0912 jaw crusher may vary with different materials and feeding sizes.

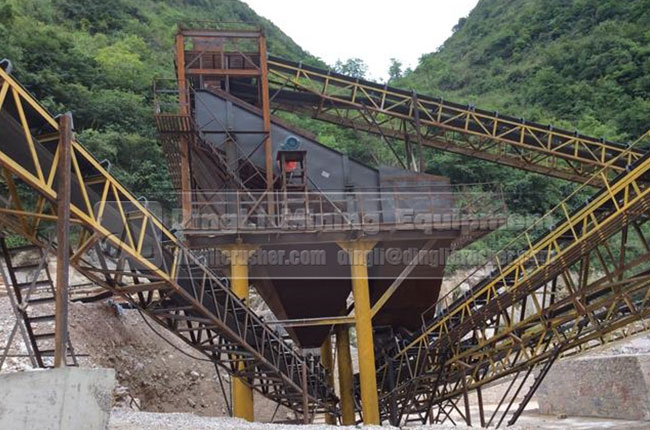

Its seen the crushing equipment is neatly arranged at the customers production site and the dust proof facility is installed in all the conveying equipment. The dust prevention measure is especially required in the junction of equipment.

Machine: ZGC1538 vibrating feeder + PCZ1615 heavy hammer crusher + 4*YKZ2460 vibrating screen + ZSJ 1218 dual rotor sand maker

Through primary crusher the unqualified aggregates will be returned to the crusher for a repeated crushing so as to obtain the finished material with sound grain shape. This gravel production line will be reformed by adding bag filter.

For applications demanding higher throughput, the PEJ Series Jaw Crusher PEJ0912 offers a powerful solution with its 900 x 1200 mm feed opening capable of processing material sizes up to 750 mm. This model is engineered for efficiency and reliability, making it a preferred choice in industries where consistent performance is critical.

The PEJ0912 boasts a substantial crushing force and a processing capacity of 180 t/h, driven by a powerful 110 kW motor operating at 730 r/min. The double-toggle design incorporates two shafts—one active and one supporting—resulting in a simple swinging action that excels in breaking down tough materials.

Featuring an adjustable discharge opening range of 130 ± 35 mm, users can adjust the output size precisely to meet their processing requirements. The hydraulic adjustment system allows for rapid changes to the discharge setting, enhancing the machine's adaptability to varying operational conditions.

Designed with the end-user in mind, the PEJ0912 incorporates features that simplify maintenance and operation. The robust frame and protective components contribute to a safer working environment, while the machine's modular construction facilitates easier servicing, minimizing downtime and maximizing productivity.

We are present worldwide and always here to help.

Get in touch today!