Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | CS315D | ||

| Mantle Diameter | 2134(7') | ||

| Cavity Type | Fine Type | Medium Type | Coarse Type |

| Closed Side (mm) | 51 | 95 | 127 |

| Open Side (mm) | 105 | 133 | 178 |

| Discharge Size (mm) | 5 - 16 | 10 - 19 | 13 - 25 |

| Processing Capacity (ton/hour) | 190 - 408 | 354 - 508 | 454 - 599 |

| Spindle Rotation Speed (r/min) | 435 | ||

| Power (kW) | 315 | ||

| Weight (t) | 110 | ||

| Overall Dimensions (mm) | 4130×3251×4454 | ||

*Note: The processing capacity of the CS315D cone crusher may vary with different materials and feeding sizes.

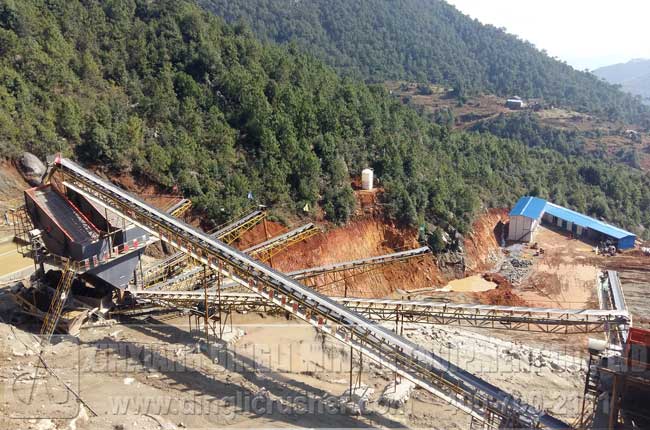

The above pictures show production site of hard rock crusher plant. Unlike traditional crushing plant it adopts only one set of hard rock crusher to complete the crushing process which greatly reduces the equipment investment and increase

It’s seen the gravel aggregate production line has large scale which can meet the customer requirement for large capacity. The dust collectors will be configured later for environment protection.

In production ba

These are the main components in direct contact with the material. In the CS315D, due to the intense crushing forces, they experience significant wear. The replacement cycle depends on factors such as the hardness of the processed material and the operating hours. Generally, for processing moderately hard materials like limestone, with continuous operation, they may need to be replaced after about 3 - 6 months. However, if dealing with extremely hard ores like granite, the replacement might be required more frequently, perhaps every 2 - 3 months. Regular inspections should be carried out to monitor the wear depth and surface condition. When the wear reaches a certain extent, such as a significant reduction in the effective crushing area or a deep groove formation, replacement is essential to maintain the crushing efficiency and product quality.

The main shaft and its associated sleeve are crucial for the stable operation of the crusher. Under normal circumstances, with proper lubrication and regular maintenance, the main shaft and sleeve can last for a relatively long time. However, if there is misalignment, excessive vibration, or contamination in the lubrication system, wear can accelerate. Inspection intervals of about 1 - 2 months are recommended. Signs of wear include scoring, pitting, or an increase in clearance. If the wear exceeds the allowable tolerance, replacement of the sleeve or even the main shaft may be necessary. This usually occurs after several years of operation, but it can be earlier depending on the operating conditions.

Bearings support the rotating parts and endure heavy loads. Their service life is affected by factors like load magnitude, rotational speed, and lubrication quality. For the CS315D, under normal operating conditions and with proper lubrication, the bearings may last around 1 - 2 years. Regular checks every 3 - 6 months should be done to monitor temperature, vibration, and noise. If any of these parameters deviate from the normal range, it could indicate bearing wear or damage. In case of excessive wear, replacement should be carried out promptly to avoid further damage to the crusher.

The gears in the CS315D are responsible for transmitting power and maintaining the proper motion of the crusher components. They are subject to wear due to continuous meshing and high loads. The replacement cycle depends on the gear material, load intensity, and maintenance. High-quality gears, when properly maintained, can last about 2 - 3 years. Regular inspections every 6 months are advisable. Signs of gear wear include tooth wear, chipping, or abnormal noise during operation. If such issues are detected, the gears should be replaced to ensure the smooth running of the crusher and prevent power transmission failures.

We are present worldwide and always here to help.

Get in touch today!