Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | Power (KW) | Chamber Type | Maximum Feeding Size (mm) |

| E-SMG200S | 160 | EC | 360 |

| C | 300 | ||

| M | 235 |

| Model | Tight Side Discharge Port (mm) Corresponding Production Capacity (t/h) | ||||||||||

| 22 | 25 | 29 | 32 | 35 | 38 | 41 | 44 | 48 | 51 | 54 | |

| EC | 126 | 138 - 173 | 147 - 230 | 156 - 293 | 165 - 310 | 174 - 327 | 183 - 330 | 196 - 306 | 205 - 256 | 214 | |

| C | 108 | 116 - 145 | 127 - 199 | 135 - 254 | 144 - 270 | 152 - 285 | 161 - 301 | 169 - 264 | 180 | ||

| M | 98 - 123 | 106 - 166 | 116 - 218 | 124 - 232 | 131 - 246 | 139 - 261 | 147 - 275 | 154 - 241 | 165 | ||

*Note: The processing capacity of the E-SMG200S cone crusher may vary with different materials and feeding sizes.

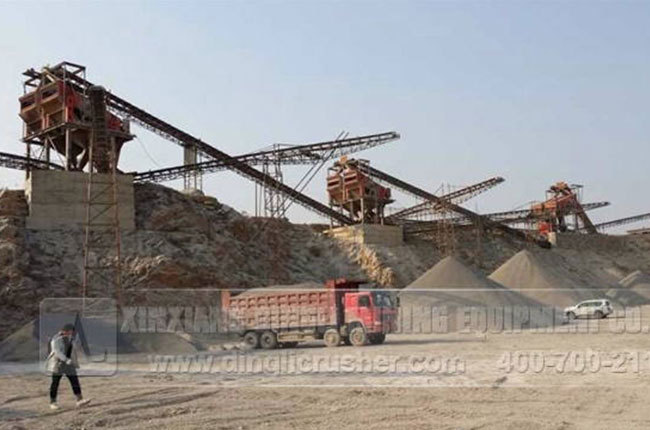

This production line is especially constructed for the building stone with wide application of finished material and optimized operation efficiency.

For crushing iron ore, DLHGC horizontal rotary crusher is selected, with a discharge requirement of less than 200mm for secondary crusher processing. Our company's horizontal rotary crusher has a feed height of about 50% to 60% compared to traditional selective crushing, which can save 60% to 70% of infrastructure construction costs.

This 1400tph production line is configured with 3 sets of vibrating screen running side by side the efficiency of which is 50% higher than that of combined screening of two screens.

The E-SMG200S single cylinder hydraulic cone crusher, as an outstanding achievement of Shanghai Sanme Co., Ltd., embodies advanced mechanical, hydraulic, electrical, automation and intelligent control technologies. It occupies an important position in the mining and aggregate industry and is specifically designed to handle the crushing challenges of hard and medium-hard materials, demonstrating efficient, stable and multifunctional characteristics.

This crusher model has a power of 160KW and offers a variety of cavity type options, such as EC, C, and M cavity types. Different cavity types have different emphases in terms of feed size and product size control, providing the basis for meeting diverse production requirements. For example, the EC cavity type can have a maximum feed size of 360mm, which is suitable for primary crushing of larger block materials; the C cavity type with a maximum feed size of 300mm performs well in crushing medium-sized materials; the M cavity type with a maximum feed size of 235mm is more focused on crushing operations with relatively finer product size requirements.

From the data of the closed-side discharge port and the corresponding production capacity, as the size of the discharge port changes, the production capacity also shows corresponding variation patterns. Taking the EC cavity type as an example, when the closed-side discharge port is 22mm, the production capacity data is not provided. But when the discharge port is 25mm, the production capacity is 138 - 173t/h. As the discharge port gradually increases to 90mm, the production capacity fluctuates between different values, such as 214t/h. This indicates that the reasonable adjustment of the discharge port size is crucial for precisely controlling the production capacity and product size. In actual production, operators can flexibly adjust the closed-side discharge port size according to the required product size and production volume requirements to achieve the best production efficiency.

With the optimized cavity design, the E-SMG200S can achieve higher production output and better product quality. Under the condition of choked feeding, it can effectively realize laminated crushing, resulting in a better product shape. For example, when processing hard materials such as granite, through laminated crushing, not only can the crushing efficiency be improved, but also the generation of flaky particles can be reduced, improving the overall quality of the product and making it more in line with the strict requirements of the construction and building materials industries for aggregates.

The method of hydraulic adjustment of the discharge port greatly facilitates the adjustment operation during the production process. It can adjust the discharge port in a timely and convenient manner, enabling the crusher to work under the choked feeding condition, reducing the wear of wearing parts and thus reducing the operation cost. Compared with traditional crushers, the replacement frequency of its wearing parts is significantly reduced. In the long run, it can save a large amount of maintenance and replacement costs for enterprises.

Due to the same main body structure of the crusher, different crushing cavity types can be obtained by simply replacing the liner, which can meet the different process requirements of coarse and fine crushing. This flexibility enables the E-SMG200S to adapt to changes in different production stages and material characteristics. In the initial stage of mining, a larger feed opening and a coarser crushing cavity type can be used for coarse crushing operations. As the production process progresses, it can be replaced with a smaller feed opening and a finer crushing cavity type for medium or fine crushing operations without replacing the entire equipment, greatly improving the versatility and resource utilization rate of the equipment.

The high-quality hydraulic technology makes the operation simple and the maintenance convenient. On the one hand, it can effectively realize overload protection and avoid damage to the equipment caused by accidental overload. On the other hand, it simplifies the crusher structure and reduces the weight. All maintenance and inspection work can be completed from the upper part of the crusher without complex disassembly and lifting operations, significantly shortening the maintenance time, reducing the downtime of the equipment and improving the continuity of production and the economic benefits of the enterprise.

The S model of the E-SMG200S adopts a large feed opening design. For example, the EC cavity type has a maximum feed size of 360mm. This design enables it to form a better match with the front coarse crushing jaw crusher and improve the processing capacity of the crushing system. When processing large-sized materials such as river pebbles, its large feed opening can smoothly accept the materials, reducing the material pretreatment process. And in some cases, it can replace the jaw crusher as a coarse crushing device, further expanding the application range and usage scenarios of the equipment and providing more production process options for enterprises.

We are present worldwide and always here to help.

Get in touch today!